A Guide to Barcode Types and Identification

Barcodes are essential for businesses. Find out about the different types of barcodes and choose one that works for your company.

Looking to optimize your delivery business? Use barcodes, and transform your last-mile delivery with Circuit for Teams.

You probably use barcodes across your supply chain — right from when the goods are dispatched from a central warehouse to when they end up in customers’ hands.

After all, there’s no other better way to track the movement of your goods.

That said, you might be using a code 39 barcode or something along those lines.

Why would you need any others, right?

There are plenty of uses. For example, some other types of barcode are better for storing more data, whereas others are better for longer transportation since they’re more resistant.

I’ll tell you about each of these types.

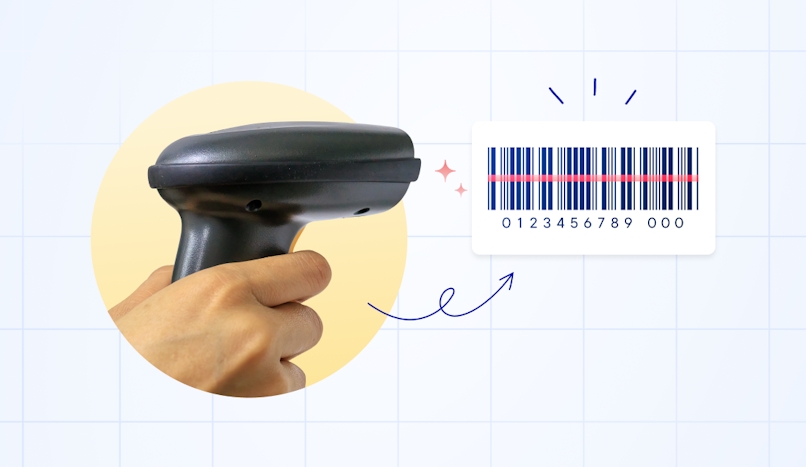

How do barcodes work?

How barcodes work is pretty interesting. Let’s break the process down into steps:

- Data entry: Barcodes — whether parallel lines or 2D symbols — pack in a lot of information about the product: weight, price, date of manufacture, and so on. This data is encoded into the barcode using a simple barcode generator website or app and printed.

- Barcode symbologies: Symbology is the process of encoding data into a barcode. There are different types of barcode symbologies. The parallel lines you see on barcodes aren’t random. They represent a code language where bars and spaces symbolize letters or numbers. The International Organization for Standardization (ISO) registers and verifies most barcode formats and symbologies.

- Scanning and data collection: Data stored on a barcode can be scanned in several ways. 1D codes are scanned using a laser beam on a barcode scanner or barcode reader, and 2D codes are scanned using a phone camera. Once the scan picks up the code, it pulls up all the information associated with it. This includes the item description, manufacturing date, expiration date, manufacturer name, weight, and country of origin. Then, it translates the code into text (or images, in the case of 2D barcodes).

The data is automatically entered into a computer when the code is scanned, saving a lot of time and reducing the chances of human error in data entry.

You only need to think back to the last time you went to a grocery store.

Imagine how much time it would have taken if the cashier had to enter product information manually.

If it was a big shopping trip, you’d have been there for a while.

Plus, there’d be more chances for errors and a higher likelihood of being charged the wrong amount for an item. Yikes.

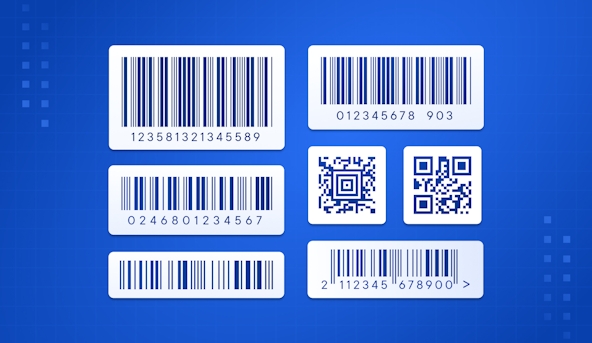

Standard barcode types

Standard barcodes have parallel lines of varying widths and spacing, with letters or numbers written under them.

If you’ve been in the delivery business for a long time, you’ve likely seen a universal product code (UPC) barcode.

It’s a common barcode that helps identify and track trade items.

UPC barcodes have unique 12-digit codes under the black lines and are used globally to identify retail products.

There are several types of barcodes, each suited to a particular kind of business. They differ from each other in the following ways:

- Size: The barcode’s size is determined by the scanning machine and the actual use of the barcode.

- Capacity: This refers to the character set or character combinations (letters and numbers) the barcode can encode.

- Linearity: This refers to the length of the scannable area on a barcode.

- Checksum: A checksum is a portion of the barcode used to verify that the information scanned from the barcode is correct. This is usually the number at the far right of the barcode. It’s also known as the check digit.

Let’s take a look at a few types of barcodes that might be helpful in your delivery business.

Code 39

Code 39 is one of the oldest and most popular barcodes.

It’s most commonly used in the automotive, electronics, health care, and defense industries.

Code 39 is a one-dimensional, alphanumeric code that includes letters from A to Z, numbers from 0 to 9, spaces, and special characters.

It’s called Code 39 because it was originally capable of encoding only 39 characters.

Now, that number has increased to 43.

Code 39 barcodes have relatively low data density, which makes them difficult to use on certain products like international packages or specialized delivery items (that need things like cold storage).

Code 128

Code 128 is an updated version of Code 39.

It’s called Code 128 because it can encode all 128 characters on the American Standard Code for Information Interchange (ASCII).

This means it can encode far more information than Code 39.

This high-density code can store large amounts of data in a small space.

It’s ideal for labeling packages for shipping and transportation since it can easily hold all the data about the type of package, mode of delivery, and place of origin.

Code 128 is used mainly in the retail, eCommerce, and delivery industries.

GS1-128

This barcode can encode all 128 ASCII characters, plus Latin-1 characters defined in ISO/IEC 8859-1.

GS1-128 is also used in the logistics and transportation industries because it can create long yet compact codes.

This helps them hold even more information in a smaller space and improve overall supply chain efficiency.

These barcodes carry information like:

- Best before date

- Weight

- Quantity

- Batch number

Codabar

Once a commonly used barcode, Codabar is slowly being phased out because of its low encoding capacity.

But a big advantage is that it’s simple to use.

Any user can create their own Codabar code using a sequence of consecutive numbers — encoding up to 16 characters with four alphabets, A to D, as start or stop characters.

Libraries, blood banks, logistics and health industries, photo labs, and even some delivery companies still use Codabar barcodes.

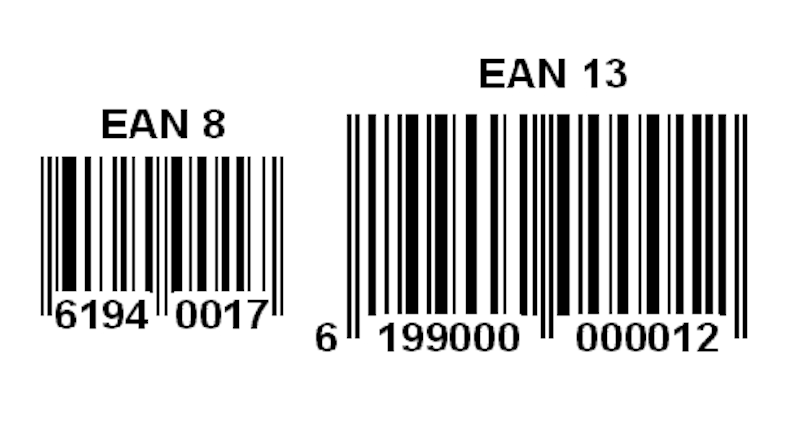

EAN-8 and EAN-13

As the name suggests, European article number (EAN) barcodes are mostly used in Europe, including Britain and Ireland.

You can commonly find them on consumer products like groceries, clothes, shoes, and more.

EAN-13 consists of 13 digits, while EAN-8 consists of eight digits.

EAN-8 can be useful for labeling small food items and stationery that don’t have space for long barcodes.

These types of barcodes encode information about the product type, manufacturer details, and retail price, and are most often used at the point of sale.

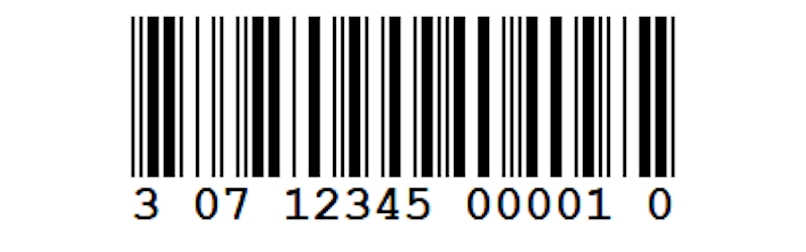

ITF-14

ITF-14, also known as Interleaved 2 of 5, is a type of code used mainly in warehousing, shipping, and distribution.

These codes have high printing tolerance and can be printed directly onto corrugated cardboard.

ITF only encodes numbers — 14 digits in all.

The code is mainly used in deliveries and has no point-of-sale (POS) use because it can’t hold a lot of complex information (like the manufacturing date or item number and price).

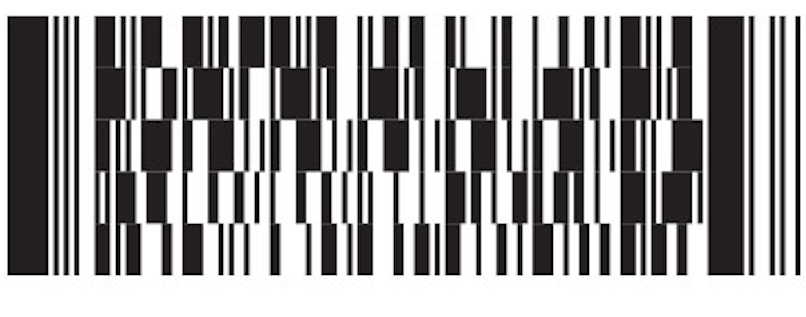

PDF417

PDF417 is a two-dimensional barcode. What does this mean?

2D barcodes encode data using two-dimensional shapes and symbols.

Linear barcodes, on the other hand, store information based on varying widths and spacings of parallel lines.

PDF147 is one of the most efficient barcodes and can store up to 1.1 kilobytes of machine-readable data.

That is a huge amount of information.

This makes it more powerful than all other 2D barcodes.

Because PDF147 has a lot of storage space, it’s ideal for data-heavy applications that need to store photographs, signatures, or biometric information.

You’ll usually find this kind of barcode on employee ID cards, airplane boarding passes, and government IDs.

Data matrix

Data matrix barcodes are also 2D and can store large amounts of data without taking up too much space.

They are smaller than QR codes — making them ideal for small products that don’t have much space for barcode labels.

Data matrix codes are designed in a way that makes them readable even in less-than-ideal scanning conditions (like low light).

They can also withstand harsh factory floor conditions and poor resolution and scanning issues.

Because of their general resilience, readability, and small size, data matrix barcodes are often found on electrical appliances and surgical tools.

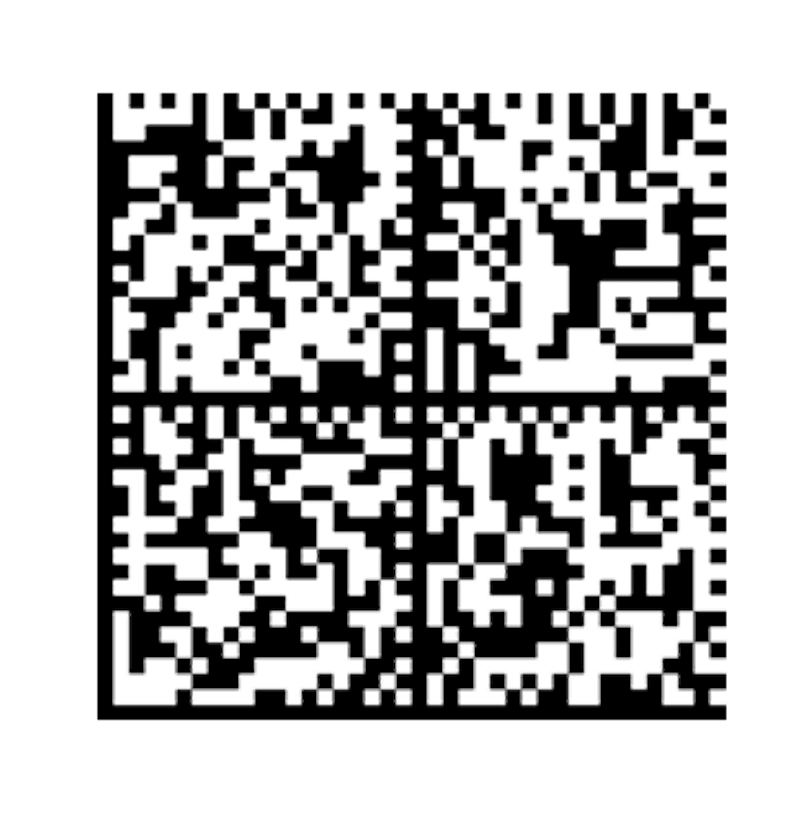

QR codes

QR codes, or quick response codes, are two-dimensional barcodes first developed by Toyota in 1994.

They were initially used to track a vehicle’s different parts during the manufacturing process.

Now, you can find QR codes just about everywhere.

Smartphones can scan and read QR codes, making them a highly useful marketing tool.

This is why you’ll see them on posters, advertisements, newspapers, magazines, storefronts, and even business cards.

They can encode more than 7,000 numbers or 4,000 letters, making them one of the most compact and versatile barcodes around.

Delivery companies use QR codes because they can encode a lot of information in one image and are typically damage-resistant.

In fact, QR codes can experience up to 30% damage due to dust, water, and other external factors and still work fine.

1D vs. 2D barcodes

Barcodes can be divided into two categories: 1D and 2D.

While both types collect and store large amounts of information within a compact set of codes, they differ in the quantity of data they can hold and their purpose.

One-dimensional barcodes are linear.

This means they use straight and parallel lines to store data.

They do this by varying the width and spacing between the lines to encode information.

So, the length or size of the barcode is based on the amount of information it holds.

1D barcodes are usually used for inventory (like POS codes) and even for making delivery and distribution more efficient.

For example, you can use 1D barcodes to track goods entering and leaving your warehouse.

2D barcodes are similar to 1D barcodes, except they encode data using two-dimensional shapes and symbols.

While 1D codes look like parallel lines with alphabetical and numeric characters written underneath, 2D barcodes have black and white dots and shapes that create patterns.

2D barcodes have a much higher storage capacity than their 1D cousins.

They can encode images, sounds, web addresses, and all kinds of binary data.

Plus, they’re designed to survive hostile conditions and preserve the data encoded in them despite damage, scratches, and low-resolution reproductions.

Square 2D barcodes also take up less space than traditionally rectangular 1D barcodes.

With different types of barcodes to choose from (like UPC-A, ISBN, MSI, POSTNET, and Aztec Code), you might be wondering which barcode will best suit your business.

For a delivery business, the most commonly used barcodes are Code 128 and MaxiCode, developed by the United Parcel Service (UPS).

They’re used to track the shipping of packages.

Shipping products yourself? Circuit for Teams can help

Handling large numbers of packages coming in and going out can be overwhelming.

Barcodes can help by increasing the speed and efficiency of data collection.

A barcode attached to a newly arrived package can tell you how to store or deliver it.

Similarly, barcodes can help drivers access this information when they’re making deliveries.

A simple scan through the company app can tell them everything they need to know — from the type of delivery to the exact delivery address.

Barcodes can also save time and money at different points of delivery, such as receiving orders, picking up orders, and during inventory management.

Instead of manually logging shipments, your employees can simply scan the code on each package to log them automatically.

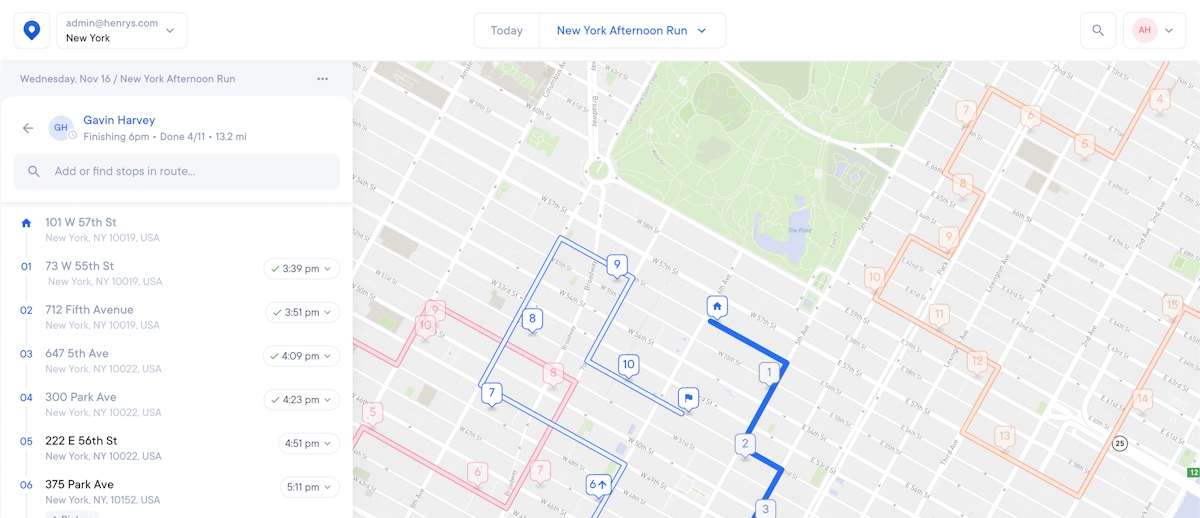

Barcodes are great, but another way to simplify your delivery process is to use Circuit for Teams.

Circuit for Teams can optimize all of your delivery routes and help you manage large teams.

Customers love it, too. Our software sends them automatic updates on when to expect their packages.

Circuit for Teams also lets you keep tabs on your drivers and see where they are in real time.

This helps you stay on top of your delivery schedule.