The Complete Guide to Improving Process Efficiency

Improve your business process efficiency with this guide. Learn top tips for process mapping to streamline workflow and reduce inefficiencies.

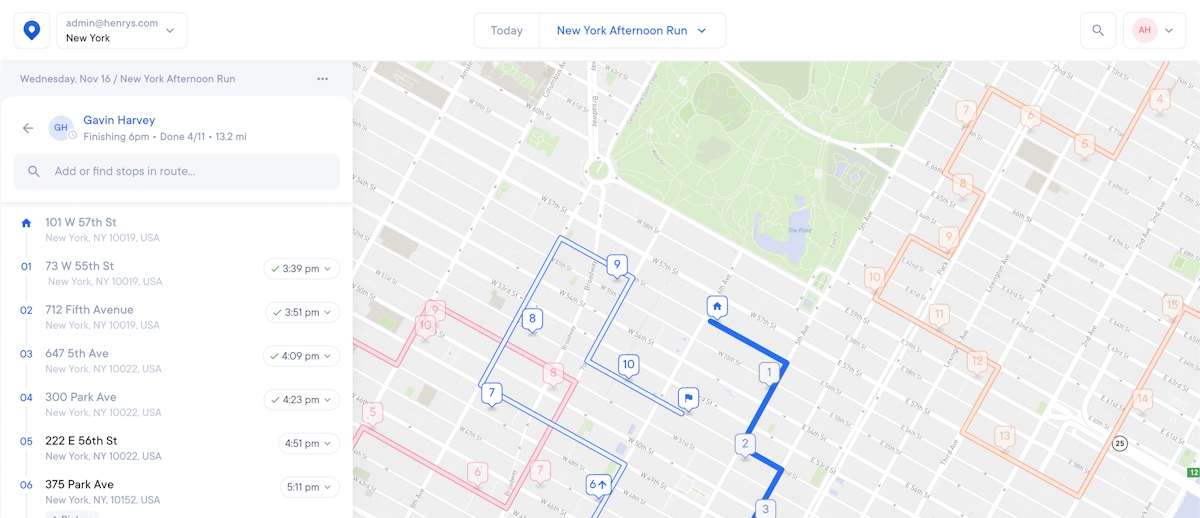

Make your delivery process more efficient with Circuit for Teams.

One of the most important steps to building a successful business is improving your process efficiency.

Henry Ford revolutionized car manufacturing with the assembly line — slashing the time it takes to build a car from 12 hours to an hour and 33 minutes.

Ray Kroc applied similar principles when he launched his business, a little restaurant called McDonald’s.

The meal assembly line and functional kitchen layout made the place a symphony of efficiency.

Today, Amazon’s warehouses create efficiency out of chaos — shipping over 1.6 million packages a day.

These businesses found ways to streamline processes, tackle bottlenecks, and make the most of their resources.

And so can you!

Process efficiency is about more than just time.

It’s about continuous improvement, resource efficiency, customer experience, and keeping your stakeholders happy.

We all know that in business, shi*t happens.

Plans are delayed, goals get off track, and things can fall through the cracks.

Before you know it, thousands of hours can be wasted on a broken template, hundreds of dollars of resources on crappy software, and tons of frustration on a disorganized system.

This is where business process management comes into play.

Business process management (BPM) is the reviewing and continuous improvement of each process in your business, so inefficiencies stop falling through the cracks.

I’ll take you through the key steps of effective BPM and how you can improve process efficiency in your business.

What is process efficiency?

Process efficiency refers to the effectiveness of your business processes.

In other words, it measures how well each step works to help you achieve your goals.

Process efficiency is about measuring outcomes and identifying where you can make improvements along the way.

You want to understand how smooth a process is, how long it takes to reach the end result, and what resources you’ll use along the way.

It’s about making sure that each action in your organization contributes to the overall success of your business — rather than just being performed because it’s a part of company policy or tradition.

For example, if it took one hour and $30 worth of ingredients to make a McDonald’s hamburger, it wouldn’t exactly be “fast food.”

And it definitely wouldn’t be a profitable business model when they’re charging $2.59 for the same burger.

Overall, process efficiency is about optimizing your processes to create the most value for your business.

By identifying areas of inefficiency and using good strategies, you can make sure each step contributes to achieving your goals.

How is process efficiency measured?

Business process efficiency comes down to these metrics:

- Overall efficiency: Start with the big picture. How’s profitability? How long does the overall workflow take from beginning to end?

- Labor productivity level: How productive are your workers, and how does this compare to their peers?

- Throughput: Is the business meeting targets on time?

- Resource utilization: Are you using resources (like equipment and tools) effectively and efficiently?

- Failure rate: How often does your process break down, and how frequently do you need to fix problems?

- Customer satisfaction: Do customers feel like they’re getting the quality of service they deserve?

- Cost-effectiveness: Are you spending more money than necessary on operations?

- Return on investment: Take a look at your bottom line. Is your process meeting organizational goals and creating revenue?

By tracking these key metrics over time, you can identify areas where you can improve business process management.

For example, if labor productivity is lower than that of similar businesses in your industry, you may need to look at the training or project management strategies used within your organization.

5 steps to improve process efficiency

You’re ready for more efficient processes in your business, but how exactly do you get started?

I’ll walk you through how to look at your current process and identify areas that need improvement.

Step 1: Thoroughly examine existing processes

Start by identifying your current processes and workflows.

You can do this through process mapping, which involves creating a visual representation of all the steps in a process.

For example, if you’re looking to improve efficiency in your manufacturing process, you might use a flowchart or diagram to map out the steps involved in the production cycle — from creating the raw materials to putting finished products on the shelves.

Process mapping allows you to see where bottlenecks occur and identify potential areas for improvement.

This is also called value stream mapping (VSM) and can be done by breaking down the process into individual steps and tracing them through the workflow.

VSM is a lean management method, meaning you focus on creating the most value for your business while minimizing waste and costs.

For example, what’s the process your team members take to create new content for your blog or social media?

This could look like a weekly team marketing meeting, research, content creation, handover to the graphic designer, scheduling posts, and final review.

How long does each stage take? Are there any delays in the process?

You may instantly see areas where the process could be improved (more on this later). But in this beginning stage, focus on perfecting the current process before investigating how to start a new process.

Step 2: Determine what works and what doesn’t

Once you clearly understand how things currently work, you can begin to look for ways to streamline the process.

One way to determine what works is to track outcomes and compare them against your desired results.

For example, if you’re looking to improve online customer satisfaction, you can track customer survey data and compare it to your established goals.

This can help you identify whether there are any areas where your processes need improvement, such as a high number of customer complaints or low levels of customer satisfaction.

Maybe your products are arriving broken and customers are unhappy.

In this case, you may want to look into better product packaging or train team members on how to handle materials safely.

Maybe your delivery process is taking too long and customers can’t track their packages.

In this case, it could be useful to offer real-time tracking and process automation with push notifications for customers when deliveries are on their way.

Another way to determine what doesn’t work is to look for bottlenecks or areas where there’s a lot of wasted time.

This may involve removing unnecessary steps, automating repetitive tasks, or redesigning the workflow to better suit your organization’s needs.

You should also open the forum to team members. Ask them what’s working and what’s not.

Your team likely has excellent insights into the root cause of what’s going wrong.

In some cases, it might be necessary to make process changes — while in other cases, it might be enough to offer additional training or resources.

Going back to our social media post example, you might look into tools and services that allow you to schedule on multiple platforms at once, so your team members aren’t wasting time scheduling posts on platforms separately.

Step 3: Create new business goals and KPIs

Sometimes, when our business isn’t meeting its goals, it’s because our goals suck.

Seriously, we sometimes have unrealistic expectations and goals that aren’t actually attainable.

We set arbitrary timelines. We fall into wishful thinking.

We want something to happen but don’t have the research to prove it will.

This is a waste of time and resources and can lead to unnecessary stress and frustration.

When this happens, we have to be bold enough to question our goals and create new ones that are attainable.

This might involve being more realistic about timelines, researching what others in the same industry have achieved, or even redefining success.

For example, if your business is struggling to attract new customers on social media, you might consider what others in your industry are doing to succeed and create new business goals based on that research.

If your goal is a million Instagram followers, you may need to rethink your goals.

You might be surprised to learn what percentage of followers are actually bots.

For instance, Nike has 46.4 million alleged fake followers out of its 168.3 million Instagram followers.

Followers aren’t a good indication of social media success and can be misleading.

And this is just one aspect of a business.

Process improvement is only as effective as our goals.

This can be a good time to step back and reassess your business goals, taking into account the realities of your industry and the resources you have available to meet those goals.

Key performance indicators (KPIs) can also help you measure improvement and success.

Some commonly used KPIs include tracking conversion rates, revenue growth, customer retention rate, and return on investment (ROI).

By clearly defining your business goals, you can start taking steps toward improving your process efficiency.

Check out our post on supply chain KPIs and metrics to measure in 2023.

Step 4: Redesign the process

Once you understand where your business falls short, the next step is to redesign the process to better meet your goals.

I’ve shared a few examples and possible solutions — things like offering additional training, using process automation, and tracking new business goals and KPIs.

Ultimately, the design of your new process must align with your goal and address the efficiency breakdown you’re experiencing.

You’ve mapped out the current process and identified what works and what doesn’t.

Now, it’s time to brainstorm ways to improve the process and make it more efficient.

This may involve making changes to established systems, revamping your workflow, or taking a step back and looking at the big picture.

This is a great time to involve your team members, as they may have valuable thoughts and suggestions you haven’t considered.

As you complete your new process mapping, be sure to compare it with the old version.

Are the changes you’ve made actually making the process more efficient?

What are the key differences?

How will this look and feel to your employees and customers?

It can be intimidating to start from the ground up. But with careful planning, you can create a new process that’s much more efficient and effective.

Step 5: Implement, measure, and improve

You’ve made changes.

You have a new process.

You have realistic goals.

Now, you need to track your progress and make improvements as needed.

This is an ongoing process.

It’s important to be flexible and willing to change course as necessary.

Determine what your KPIs are and monitor them regularly.

Maybe you’re trying to cut operational costs and identified transportation costs as a problem area.

Set your transportation budget and track how you’re doing.

Maybe you’ve tried a new process automation tool, and it’s not working as you expected.

You’re still spending the same amount of time and amount of effort as you were with the old process.

Don’t be afraid to make adjustments and try something else.

The key is to keep moving forward, making incremental changes and improvements along the way.

Ultimately, process efficiency is only as effective as your willingness to think about what’s working and what isn’t, and adopt the necessary changes moving forward.

With hard work, creativity, and a willingness to learn from your mistakes, you can create an efficient and effective process that achieves your business goals.

Key causes for process inefficiencies

Several things can contribute to process inefficiencies, including:

- Unclear goals: If your goals aren’t clear, it can be difficult to create process improvements that show results.

- Lack of training or support: Ineffective training or lack of support can lead to confusion, mistakes, and inefficiencies.

- Lack of communication: A breakdown in communication can mean processes aren’t followed as they should be, resulting in disappointing outcomes.

- Poor process documentation and organization: A lack of clear documentation can make it difficult to identify and address inefficiencies, especially during transitions.

- Technology issues: Outdated or insufficient technology can be a major barrier to effective process management.

Handling the shipping process yourself? Circuit for Teams can simplify it

If you’re handling your business’s shipping and delivery process, you know firsthand that there’s a lot of room for inefficiencies and frustrations.

Circuit for Teams can help you simplify your last-mile delivery process with route planning for multiple drivers.

Eliminate wasted delivery time, cut down on the number of trips needed to make your deliveries, and manage your entire delivery process from start to finish.

With Circuit for Teams, you can create and distribute routes for multiple drivers, collect proof of delivery, and automate customer notifications so your customers always know where their orders are and when to expect delivery.

Check out how this company shaved more than eight hours off its payroll process with Circuit for Teams.

Over 4,000 businesses use Circuit for Teams to save time and money on their logistics and last-mile delivery needs.