How to Measure OTIF

Learn how to calculate your OTIF scores and improve OTIF performance for better supply chain management.

Deliver orders within the correct time windows and easily manage your drivers with Circuit for Teams.

Delivery companies, retail suppliers (like Walmart), and micro-fulfillment businesses often use the “on-time in-full” or OTIF metric to figure out the percentage of their total deliveries completed on-time in-full.

Companies calculate OTIF slightly differently — but it’s typically the percentage of on-time and complete deliveries compared to the total number of ordered deliveries.

Here’s the basic equation to calculate that percentage:

OTIF (%) = (number of on-time and complete deliveries / total number of ordered deliveries) x 100

An OTIF of 100% means the entire order arrived at the customer’s home within the expected time window.

A low OTIF score could mean OTIF fines, unhappy customers, and lower profits.

So, how can you make sure you have enough inventory and your drivers consistently arrive at your customers’ homes on time?

Keeping enough inventory to ship out and scheduling accurate delivery times are two ways to get a great OTIF score.

What is on-time in-full (OTIF)?

Funny enough, not everyone agrees on the OTIF definition.

But we’re getting there.

While OTIF as a supply chain key performance indicator (KPI) has been around for years, the metric really blew up when Walmart updated its Must-Arrive-By-Date (MABD) requirements with a new OTIF initiative in August 2017.

In 2020, Walmart doubled down on its OTIF rules, increasing its mandatory OTIF percentage for all its suppliers to 98% — or face substantial OTIF fines for inaccurate deliveries.

The OTIF supply chain metric has grown in popularity, and there’s some consensus on how to define OTIF.

In June 2019, a McKinsey study found that 92% of major retailers and manufacturers believed it’d be valuable to develop an industry standard for OTIF.

Based on how respondents defined and used OTIF, McKinsey developed a suggested definition for OTIF that covers most retailers’ OTIF tracking needs.

Companies meet “on-time in-full” status when the complete case quantity (not “order” or “line item”) arrives at the shipping destination by the customer’s requested delivery date (or the “must arrive by” date).

This definition makes important distinctions regarding a “complete order” and its “delivery date.”

First, McKinsey found that companies often count a complete order by each product case rather than by an individual order or a single product.

And the delivery date is defined as the customer’s preferred delivery date.

This is different from the supplier’s promised delivery date or the estimated time of arrival — which isn’t always the same as the customer’s preferred delivery window.

McKinsey suggests the window starts with a “one-day early allowance” and closes on the delivery date at the end of the customer’s workday.

So, technically, the OTIF equation is:

OTIF (%) = (Number of complete cases delivered within the customer’s preferred time window) / (total number of cases ordered by customer) x 100

But Walmart doesn’t actually keep just one OTIF score for its suppliers.

Instead, the retail giant comes up with individual scores for each aspect of OTIF, including in-full percentage, early percentage, late percentage, and unfilled percentage.

The difference between OTIF and OTD

If you’re managing your company’s supply chain, you’ll probably hear about both OTIF and OTD.

They sound the same, but there are important differences.

OTD stands for “on-time delivery.”

While it’s similar to OTIF, OTD is less specific — it doesn’t consider whether the delivery was full versus partial, just if it was delivered.

OTD also typically allows for a larger early delivery window.

While OTIF expects companies to complete deliveries within a specific time window, OTD simply measures whether the delivery was late.

You can see the differences between OTIF and OTD by comparing the equations used to calculate these two KPIs.

OTD (%) = (Number of on-time deliveries) / (total number of deliveries) x 100

For example, if your drivers complete ten late deliveries in a month and 500 total deliveries, your company’s OTD would be 490 divided by 500 for an OTD metric of 98%.

OTD is useful for delivery companies with more lenient delivery windows compared to eCommerce stores like Amazon (which promises super-quick delivery).

If you want to improve the customer experience by delivering early, OTD might be a good option.

The importance of OTIF

Delivery managers use OTIF scores to understand how efficiently their company delivers orders to customers — whether by their in-house delivery team or a third-party shipper.

You can use this KPI to gain an overall understanding of how well your supply chain is working.

You might be able to identify bottlenecks in specific phases of the process, like a slow packing team or avoidable lags in purchasing.

For example, if your “in-full” metrics for a certain customer are worse than you’d like, look at other KPIs for places to improve.

And delivery managers aren’t the only ones tracking OTIF scores.

Retailers constantly needing new inventory use OTIF metrics to track which shipping partners are reliable and which aren’t.

And many retailers, like Walmart, fine suppliers every time a delivery isn’t “in-full on-time.”

OTIF fines help businesses make up for lost revenue caused by missing on-shelf inventory and disruptions caused by orders that arrive early or late.

For example, Target charges OTIF fines of 5% of the cost of any goods that don’t meet their OTIF requirements.

And CVS charges a 1.5% penalty for orders filled below 95% and 3% for orders below 85%.

OTIF as a KPI

Even if you’re not supplying inventory to a major retailer that uses OTIF fines, keeping a good OTIF score is still important for your business.

In a 2019 study on how suppliers can satisfy retailers, 100% of retail buyers said a supplier’s ability to complete deliveries on time impacted their willingness to work with them.

And 73% said they ended partnerships with suppliers because of delivery issues.

Besides helping you make customers happy and keep their business, OTIF metrics can help you understand supply chain performance and identify the root causes of any issues.

Everything from product procurement to warehouse picking and even delivery route planning can affect your OTIF performance.

Track OTIF to keep tabs on your supply chain management.

What is a good OTIF benchmark?

Base your OTIF targets on your customers’ requirements and your abilities.

You might even have different OTIF benchmarks for different product lines.

Although 100% is technically a perfect OTIF score, keeping a 100% OTIF rate may not be ideal for your business.

For example, if you always have enough inventory to ship out and deliver at precisely the right times, that could indicate a problem with surplus inventory in your warehouse.

(Learn how to calculate your inventory turnover ratio and why it’s important.)

While high inventory might help with customer satisfaction, you risk tying up money in extra inventory that’s just sitting on your shelves.

OTIF is important, but you must weigh its importance with other metrics.

As long as your OTIF performance meets your customers’ needs — like 98% for Walmart — you’ll be able to keep your customers happy while also managing your inventory management needs.

How to improve OTIF deliveries

Here are some OTIF improvement tips that can help you increase the number of deliveries you complete “on-time in-full”:

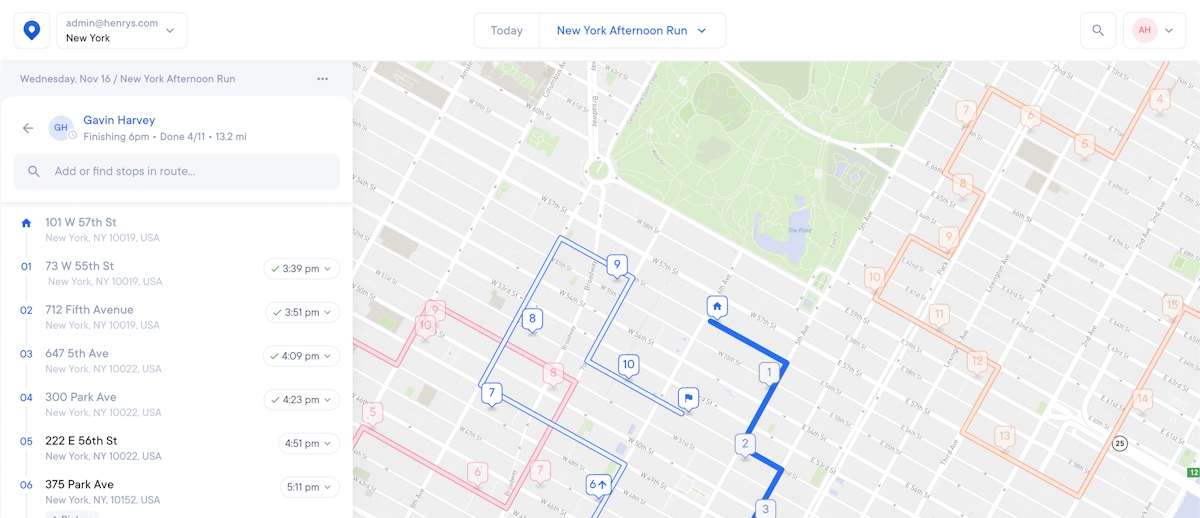

- Optimize routes to meet expected delivery windows. With route optimization software like Circuit for Teams, you can set priority rules and delivery time windows for orders — so deliveries always arrive at the correct time.

- Track orders and prioritize delayed deliveries. With real-time visibility into the status of orders in transit, you can adjust when deliveries are running late to avoid missing promised time windows. Circuit helps with that, too.

- Request a lower minimum order quantity. If you’re struggling to meet the “in-full” part of your OTIF requirements, you could improve your OTIF metric by asking customer(s) if they’ll accept a lower minimum order size.

- Request more reasonable delivery due dates. Your customer may not realize that their expected delivery date is too hard for you to meet regularly. Communicate to come up with a more practical schedule so you’re both satisfied with the arrangement — and you maintain a good OTIF metric.

- Choose the best order fulfillment strategy. When developing a process for shipping orders, consider the different order fulfillment strategies and make sure you’re using the best one for your business.

- Prevent delays with vehicle maintenance. When your delivery vehicle breaks down on the road, the orders in transit still need to get to their destination. Reduce this by regularly servicing your delivery vehicles with preventative maintenance.

- Improve your inventory management. Making sure you have enough product to ship out can help you keep acceptable “in-full” OTIF scores. Check out our posts on capacity planning and demand forecasting.

Interested in more tips on shipping logistics? Review our complete guide to shipping logistics in 2022.

Circuit for Teams gets drivers where they need to go — on time

Getting high OTIF scores doesn’t have to be a logistical nightmare.

From small plant shops making local customer deliveries to larger wholesale suppliers, all types of delivery companies can get good OTIF scores by prioritizing smart inventory management and route optimization.

For example, you can set specific delivery windows for each order by using Circuit for Teams to manage delivery routes.

That way, your orders are always scheduled to arrive at your customer’s home right on time.

Plus, Circuit helps you send accurate ETAs to customers, reroute deliveries to avoid delays, collect proof of delivery, and export data to find supply chain bottlenecks.