Supply Chain Bottlenecks: Causes, Challenges, and Solutions

What are the causes, challenges, and solutions to supply chain bottlenecks? Find out here, and learn how to optimize your supply chain and increase efficiency.

Make your supply chain management more efficient by using Circuit for Teams for last-mile delivery.

Supply chain bottlenecks can be a huge pain for you as a business owner, but they’re also a huge pain for customers. Whether the issue is with the global supply chain or a step of your order fulfillment process, bottlenecks can cause shipping delays, backlogs, and lost revenue.

No matter the root cause of a supply bottleneck, you need to know how to respond — or, better yet, prevent it in the first place.

This article will explain the causes of supply chain bottlenecks and how they can hurt your business, plus some solutions for managing and preventing them.

Key takeaways

- Root causes of supply chain bottlenecks can include global trade issues or local labor shortages.

- Poor transportation infrastructure can hurt your supply chain due to shipping and delivery delays and negatively affect your company’s reputation and customer loyalty.

- Building a resilient supply chain that can continue operating during supply chain disruptions is key to meeting consumer demand and expectations.

- Implementing new technology, improving delivery infrastructure, and increasing production capacity can help you prevent potential bottlenecks in your supply chain.

What is a supply chain bottleneck?

A supply chain bottleneck is any point that slows or stops the movement of goods through the supply chain process. Bottlenecks can happen for various reasons, such as labor shortages, component shortages, infrastructure problems, or, in the case of the 2021 Suez Canal incident, a giant container ship getting stuck.

Sometimes, bottlenecks just slow things down a little. For example, your distribution center’s Wi-Fi might go down, putting you a day behind on orders.

Or, they can slow things down a lot. Remember at the start of the coronavirus pandemic when lockdowns and increased online shopping caused a huge delay in delivery times for just about everything you ordered online?

In other instances, bottlenecks can cause a supply chain crisis with huge negative chain reactions (we’re looking at you, Suez Canal boat).

Bottlenecks cause problems for businesses in several ways. If you’re having a hard time getting a certain material due to a shortage, you might not be able to meet customer demand. Unmet demand equals lost revenue.

Similarly, a bottleneck in your order fulfillment process could cause late deliveries and disappoint customers. Unhappy customers can lead to less brand loyalty and lost revenue.

Challenges caused by supply chain bottlenecks

Supply chain bottlenecks can negatively impact your business. Here are just a few of the challenges bottlenecks can cause:

- Increased costs: Bottlenecks can hike up costs of materials, shipping, and products. You’ll either have to hike up your own prices to accommodate for your higher overhead — potentially alienating customers — or eat the loss.

- Delivery delays: This common type of bottleneck is one we’ve surely all dealt with. When your materials are delayed, your order fulfillment slows down. Longer order delivery times mean unhappy customers. Unhappy customers are less likely to return to your business, costing you money.

- Customer dissatisfaction: Customers don’t usually know the nitty-gritty of supply chain issues. They just know that their order is more expensive or slower to arrive. Unsatisfied customers are less likely to order from you again, recommend you to their friends, or leave positive reviews, which can hurt your bottom line.

- Lost revenue: Increased costs, delivery delays, and customer dissatisfaction can make you lose out on revenue. Lost revenue means lower profit margins, less opportunity to grow your business, and more headaches down the road.

Causes of supply chain bottlenecks.

Supply chain bottlenecks don’t just appear out of thin air. Here are some of the most common causes of bottlenecks.

Lack of inventory visibility

Inventory visibility is the ability to see and track your inventory: how much you have, what products you have, and where it all is. Managing your inventory can get complicated when you have lots of SKUs and multiple warehouses.

When you don’t have a firm handle on inventory visibility, it can result in tough situations like:

- Allowing customers to order an out-of-stock product

- Not knowing where an item is, delaying order packing and shipping

- Not reordering in-demand products, causing a hot item to be on backorder

Canceling orders for reasons like these can lead to disgruntled customers and lost revenue. Slow orders can also hurt your reputation and your chances of great reviews. Plus, backorders can make you vulnerable to customers going to your competition for the same or similar products.

Poor communication

Poor communication between suppliers and vendors can also cause supply chain bottlenecks. For example, your supplier might not tell you about supply constraints, raw material shortages, or delays on certain products.

Resulting stock issues can cause order issues, and ultimately, issues with your customers who don’t want to wait for their orders. And when you don’t have the right inventory in the right quantities, you’ll lose sales and potential revenue.

Limited production capacity

Limited production capacity can look different depending on your business. It could mean:

- Having insufficient labor to fulfill all your orders

- Running out of warehouse space to hold inventory

- Not having the right technology to aid material procurement and order fulfillment

When your production capacity doesn’t meet demand, you’re bound to fall behind or miss out on potential orders. Slow order fulfillment can also lead to customer dissatisfaction, hurting your brand loyalty and bottom line.

Inadequate transportation infrastructure

You rely on transport to deliver goods to your warehouses and your customers, and poor transportation infrastructure can cause a huge supply chain bottleneck. Here are some examples of transit bottlenecks:

- Delayed shipping from your supplier due to workforce shortages

- Delayed shipping to your customer via carriers like UPS, FedEx, and USPS due to demand surges

- Slow last-mile delivery due to a lack of proper technology or a shortage of truck drivers

Shipping problems can cause your customers to wait longer for their orders. As explained above, this can hurt your brand’s reputation and cost you repeat customers.

How to prevent supply chain bottlenecks

Preventing supply chain bottlenecks can help your business continue to run smoothly. Let’s review some ways to prevent them.

Inventory management

Inventory visibility optimization will help you track your inventory and forecast for reorders. When you know where everything is and are prepared with the proper inventory to fulfill orders, you’ll run into fewer supply chain disruptions.

One way to improve your inventory visibility is by implementing an inventory management system. These software programs help you track your inventory all in one place.

Some examples of inventory management systems include Cin7, NetSuite, and QuickBase. Many of these programs utilize automation to make sure you have enough stock on hand.

Knowing where all your inventory is and how much you have in stock can help you fulfill orders quicker. It will also prevent you from having too little or too much product. This can save you money and keep your orders running smoothly.

Improving communication

Improving communication with both your suppliers and your customers can help you prevent supply chain bottlenecks and mitigate their effects when they do happen.

Take the following steps to improve communication with your suppliers:

- Set clear expectations

- Establish and communicate ways to measure performance

- Be transparent and honest to build trust

- Have occasional check-in meetings

It also helps to communicate with your customers when things go wrong. They appreciate honesty and transparency, so they might be more loyal to your business if you explain what went wrong and how you’ll make it right.

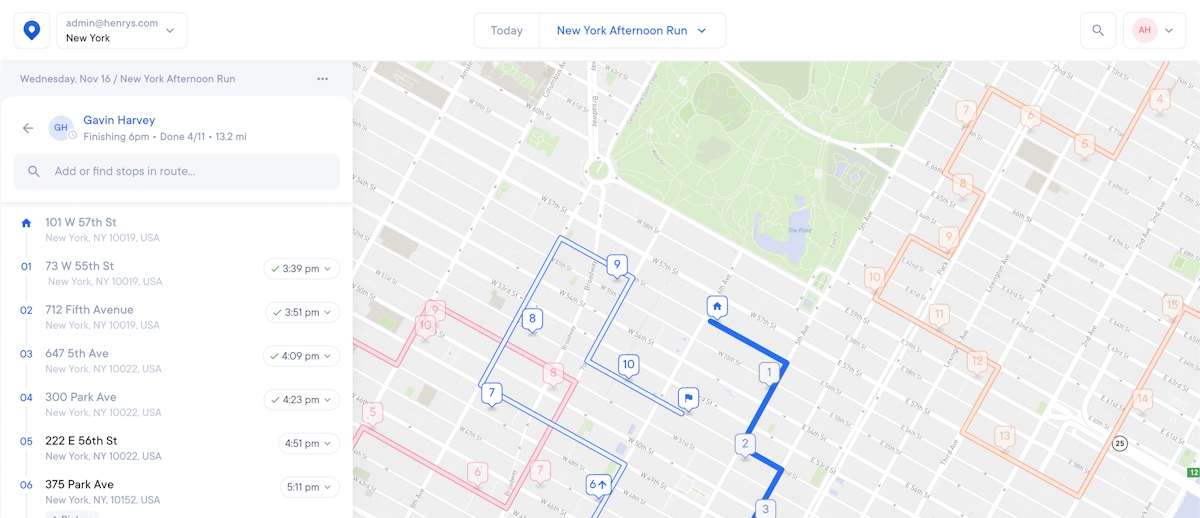

For example, Circuit for Teams lets you and your delivery drivers notify customers to let them know if there’s been a change or update to their delivery status and to give them an ETA.

Increasing production capacity

This can help prevent bottlenecks by making it possible to meet demand surges and increased business. To increase your production capacity, try the following:

- Upgrading systems, management software, and equipment

- Increase staff

- Assess your order management system and fix pain points

Increasing production capacity means your business can handle more orders, leading to more profit.

Streamlining transportation

Streamlining your transportation can help your deliveries reach customers in time, improving customer satisfaction and brand loyalty. Plus, you’re less likely to issue customer refunds when items arrive on time and in the proper condition.

One of the ways to streamline transportation is by partnering with a third-party logistics provider who can handle all your order packing and shipping.

Alternatively, you can partner with a specific carrier, such as USPS or FedEx. Using the carrier closest to your distribution center will also help you cut down on transit times and costs.

Lastly, you can handle last-mile delivery on your own. This gives you more control over your deliveries, allowing you to better meet customer expectations.

Try Circuit for Teams to seamlessly manage your last-mile delivery. New features let you manage multiple depots from one app, edit routes in real time, and offer dynamic or fixed delivery windows to your customers.

Contingency plans

Contingency plans can help you pivot when supply chain disruptions happen.

A contingency plan includes the steps you’ll take if bottlenecks pop up. Here are some options you might consider when making a contingency plan:

- Take a tiered approach when choosing suppliers, so you don’t rely on just one for everything. It’s also good to have backup suppliers for emergencies.

- Consider investing in business interruption and supply chain insurance to cover some financial loss in the case of a large disruption (like the COVID-19 pandemic).

- Increase your safety stock to avoid supply chain shortages, especially for products with long lead times.

- Regularly review and update your contingency plans to account for new challenges.

New technology

Upgrading your business’ technology can also help prevent supply chain bottlenecks.

You can use the technology you already have to level up, like leveraging and examining your first-party retail data. Sending your retail data to your suppliers so they know exactly what you need and when can also help.

Another option is utilizing artificial intelligence (AI) to help with demand forecasting, purchase lead time estimation, and more. Robots can do a lot these days.

Lastly, you can get new software to help prevent supply chain bottlenecks, such as inventory management systems, warehouse management systems, and delivery management systems (like Circuit for Teams)e.

Upgrades like these can improve your supply chain visibility, allowing you to track each part of your supply chain cycle and helping you decrease disruptions.

Delivery logistics are key to a healthy supply chain

Getting orders to their final destinations is a huge part of the supply chain. Keep your supply chain healthy and happy by upping your delivery logistics game.

Imagine you order from an eCommerce business for the first time and get your order in a timely fashion without any errors. You’ll be much more likely to order again, leave a positive review, or recommend the company to a friend when they’re looking for a similar item.

But if the item is late, you’ll just want a refund. You can prevent your customers from feeling this way by taking delivery logistics into your own hands.

Try Circuit for Teams today — it lets you manage every aspect of last-mile delivery from one place, including communicating with your customers and truck drivers.