10 Tips to Improve Inventory Management Processes in 2023

Improve your inventory management process in 2023 with these ten pro tips. From forecasting to choosing the right technology, we've got you covered.

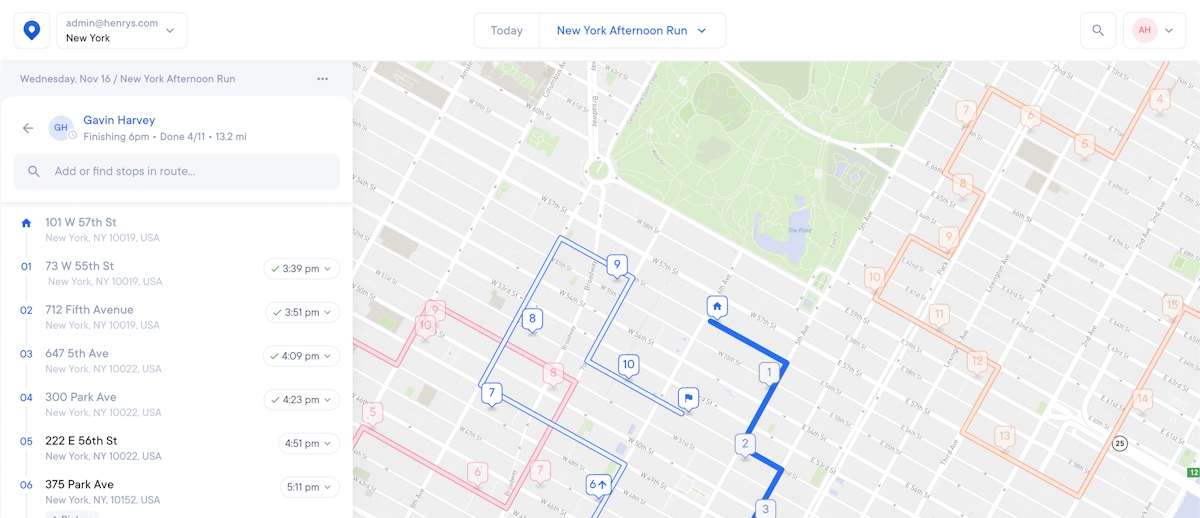

Circuit for Teams lets you easily track and manage your shipped inventory with real-time route and delivery updates.

Inventory management is a tedious process, and keeping up with your business’s ever-changing needs can be difficult. But you can improve your inventory management process to save time, money, and effort.

This post shares ten tips on how to optimize your inventory management process. These strategies — along with a powerful inventory management system — can help you maximize cash flow, reduce human errors, and improve customer experience. They can also help you reduce time-consuming tasks like manual data entry from spreadsheets.

Read on for everything you need to know about improving inventory management processes in 2023.

Key takeaways

- Demand forecasting helps you make sure your inventory is always ready to meet customer demand.

- Automating inventory management with POS systems and enhanced perpetual inventory systems can reduce excess inventory, improve turnover, and avoid overstocking or understocking.

- A Just-in-time (JIT) system minimizes holding costs and maximizes warehouse space by keeping minimal inventory on hand, making it especially useful for food and beverage businesses where inventory can spoil.

- Regular inventory audits improve inventory management by pinpointing discrepancies, highlighting warehousing and replenishment issues, improving inventory accuracy, and helping you evaluate the effectiveness of your inventory software and POS systems.

The importance of inventory management

No entrepreneur wants to see their hard-earned profits slip away. Imagine you own a clothing store and have invested in 4,000 T-shirts. A few months later, 2,500 are still sitting on the shelves.

That’s a lot of dead stock tying up your cash flow, and you may not recoup its cost if the stock remains unsold.

As another example, let’s say you run a restaurant and buy too much perishable food, like fresh produce. The limited shelf life means you must act fast so the food sells in time (or you risk losing a large amount of money).

Proper inventory management prevents stock issues in the long run. Track costs, supplier details, and upcoming orders so you’re always prepared and stocked with the essentials.

Of course, inventory management is time-consuming. It can mean manual data entry from spreadsheets and repetitive tasks like cycle counting and physical inventory counts.

That’s where the right inventory management system can help. It can automate many of these time-consuming tasks while giving greater accuracy and control.

For instance, you can use barcodes, SKUs, or radio-frequency identification (RFID) tags to track stock and prevent overstocking, spoilage, or out-of-stocks. You can also set up triggered workflows to automatically alert you when it’s time to restock and create purchase orders with the click of a button.

And if you have an eCommerce business, you can also enjoy an integrated omnichannel experience by connecting your sales channels (marketplaces) and setting up automated inventory feeds. This can help you keep up with customer demand and make sure the right items are available at the right time.

10 ways to improve your inventory management

Establishing the right inventory management techniques is an important first step toward optimizing your business, but it’s not enough. You must take the time to understand your current inventory management process and apply strategies to drive improvements.

Here are 10 tips that can help you optimize your inventory management process:

1. Forecast demand

Demand forecasting gives you a glimpse into the future and helps you make decisions to maximize profits and reduce costs. You can analyze trends in consumer behavior, sales history, and customer profiles and account for seasonal variations and market conditions.

Use sales reports and customer data to accurately create an overview of sales patterns and forecast demand. Other methods include analyzing market research, industry trends, and news reports.

AI-powered demand forecasting tools can also help you make more informed decisions. These use algorithms and data science to predict customer demand and help you plan reorder points accordingly.

2. Optimize warehouse layout

A bad warehouse layout can be a major hindrance to efficient inventory management. Optimize your warehouse by organizing it into distinct categories, so you can find items quickly and easily.

Grouping similar items or designating certain sections for raw materials, finished goods, or overflow items can speed up the process of locating and retrieving products. Additionally, you can create a “fast-moving” section where you store goods with a higher turnover rate.

Organizing your warehouse layout also helps you make better decisions about inventory levels and stocking up on specific items. You can quickly identify when you need to reorder and keep track of stock levels in real time, so you’re never out of stock or overstocked.

3. Use real-time tracking

There are many ways to track and manage inventory, but one of the most important aspects is real-time tracking. This refers to a system of keeping up-to-date records on all aspects of your inventory, and includes ordering, receiving, and shipping customer orders and understanding demand.

Real-time tracking is essential for proper inventory management, helping retailers and small businesses keep their cash flow steady, reduce waste, and maximize the customer experience.

You can use a few tools for real-time tracking in your inventory management system, such as barcodes and radio frequency identification (RFID). These are some of the quickest and most effective ways to track inventory in real-time, as they allow you to easily scan products and keep track of stock levels.

Another method is cycle counting: regularly auditing your inventory for accuracy. It involves randomly selecting small batches of products from your warehouse, counting them, and comparing them against inventory records.

4. Analyze data

Data analysis is a useful tool for understanding trends in customer demand. It helps you forecast demand so you can manage your inventory more efficiently. It also helps you optimize your supply chain, manage cash flow, reduce waste, and increase profitability.

Data-driven inventory management can help you prepare for seasonality, reduce shortages or overstock, and make sure customers get their orders on time.

Get the most out of your data by thinking beyond spreadsheets. Consider using inventory management software or apps.

These tools can help you automate workflows and monitor inventory levels in real time, reducing the chance of human error. The right tools can help you gain access to everything you need to effectively manage your inventory.

5. Use a just-in-time (JIT) system

A just-in-time (JIT) type of inventory management is an effective way to make sure customers get their orders in a timely manner.

It aims to decrease inventory levels, lower holding costs, and optimize the supply chain. This approach is gaining popularity, as it enables companies to fulfill customer demands while utilizing limited warehouse space.

Rather than stockpiling large quantities of products, JIT means ordering inventory as needed. This needs close coordination between suppliers and customers, efficient planning, and just-in-time logistics techniques.

To practice JIT delivery, suppliers need to sync orders with delivery schedules. This helps minimize the storage problem and maximize productivity.

Food and beverage businesses are a great example of where JIT inventory management can come in handy. Restaurants must order food items daily based on customer orders for optimal freshness while keeping inventory levels low.

JIT is also an effective approach for retail businesses. Instead of maintaining a large inventory, retailers can monitor customer demand and order items as needed.

6. Set up safety stock levels

Safety stock levels are a critical part of inventory management. They refer to the extra inventory businesses keep on hand to prevent out-of-stock situations.

Business owners must set up safety stock levels to have enough inventory on hand when customers make orders. You can calculate safety stock based on factors like lead times, inventory turnover, and demand fluctuations.

Businesses often use tools like Excel to calculate safety stock levels. But inventory management software can give a more detailed analysis and insights into the data, automate safety stock calculations, and reduce the chance of human error.

7. Improve communication

Good communication helps keep suppliers and customers informed. Communicate with suppliers to set expectations for lead times, plan inventory levels accordingly, and reduce order fulfillment errors.

Aside from suppliers, communicating with your customers so they’re aware of stock-outs and other issues is important. This keeps everyone on the same page and prevents unpleasant surprises that may result in lost business.

8. Automate

You can use automation to streamline processes like warehousing and replenishment and enhance inventory management functionality with tools like point-of-sale (POS) and perpetual inventory systems. Automation also improves inventory turnover and reduces the chance of excess inventory.

Your economic order quantity (EOQ) is one of the best things to automate. EOQ is the optimal amount of inventory to purchase at one time based on factors like lead times and demand. This helps you avoid overstocking or understocking.

You can also use automation to improve supply chain management by giving visibility into your entire supply chain. This helps with accurate order fulfillment and timely shipments.

9. Prioritize inventory accuracy

Accurate inventory records are essential for effective inventory management. Poorly monitored inventory levels can lead to out-of-stocks, overstocking, and lost revenue.

Understanding inventory turnout ratio and inventory shrinkage is essential to improve inventory accuracy. These tools give you a better understanding of how much inventory you need and when.

The inventory turnout ratio shows how quickly inventory sells and gives insight into potential sale trends. Inventory shrinkage measures the amount of inventory lost due to theft, damage, or other factors. This metric will give you a better understanding of the impact of these losses and insight into potential improvement areas.

10. Conduct regular audits

Managing inventory the right way means auditing the process from time to time to identify discrepancies between the recorded and actual inventory and issues with warehousing and replenishment processes. Inventory control is another key benefit of conducting regular audits, as it helps maintain accurate inventory levels and reduce inventory costs.

Additionally, inventory audits help determine the effectiveness of your inventory software and the functionality of your POS system. Regularly auditing your inventory means you can identify areas needing improvement and make necessary changes for inventory accuracy and efficiency.

Managing inventory all the way to a customer’s door

Delivery management is integral to the supply chain. You're responsible for your inventory until it reaches your customer’s door.

That’s where Circuit for Teams comes in. It’s designed to help manage your last-mile delivery, saving hours of planning and letting you prioritize certain stops.

You can also copy and share proof of delivery (POD) documents, track shipments in real time, automate route optimization, and communicate delivery status updates to customers.

Take control of your delivery operations by optimizing your last-mile delivery with Circuit for Teams today and see how it can improve your bottom line.