Perpetual Inventory System: Benefits, Formula, and Example

Many businesses use perpetual inventory systems for their practicality and benefits. Learn more about them here.

No matter how organized your items are, you must also deliver them. Efficiently manage deliveries with Circuit for Teams.

Businesses use perpetual inventory systems to track inventory levels in real time.

This is especially helpful in industries like grocery stores or hardware stores that sell large quantities of items.

Perpetual inventory systems continuously update inventory records as they’re received, returned, or sold.

It’s super useful, offering accurate and up-to-date information about current inventory levels.

It also comes with other benefits, like helping stores manage their physical inventory count and preventing the risk of overstocking items or using the dreaded “out of stock” sign 🚧.

Don’t be put off by the word “formula” in this post’s title. I’ll give you the lowdown on everything perpetual inventory systems.

It’s a lot like a perpetual motion machine for businesses, but cooler. And it obeys the laws of thermodynamics 😊.

Key takeaways

- Perpetual inventory systems help businesses managing large amounts of products track their inventory in real time.

- The system makes preparing financial statements easier by making it quicker to calculate your inventory’s financial value and reduce admin tasks.

- A perpetual inventory system is more expensive in the short term but quicker than the periodic system.

What is a perpetual inventory system?

A perpetual inventory system is a powerful tool for your business to track inventory accurately and efficiently.

It’s a great option for retailers managing large amounts of items, like grocery stores 🥫.

With a perpetual inventory system, you automatically log every transaction in real time, including purchases, sales, and returns.

It can also help you with demand forecasting, so you know when to reorder and restock products.

The last thing you want is to deal with backorders — which can piss customers off.

(Just in case, though, we’ve got a handy guide. 🤫)

Now, that’s what we call convenience.

How do perpetual inventory systems work?

Perpetual inventory systems work by updating and managing inventory records as you buy and sell goods.

It’s in the name!

This accounting method offers an accurate, efficient, and labor-saving way to track your inventory balance.

(As we’ll discuss later, the more traditional periodic inventory system relies on updating records after a certain period.)

A perpetual inventory system involves:

- Recording inventory levels. The first step is understanding beginning inventory levels for all products by placing barcodes on each product.

- Tracking inventory movement. A perpetual inventory system automatically updates inventory levels in real time whenever a product is bought, sold, or returned. This works under the first in, first out (FIFO) method, which assumes that goods arriving first are the first to be sold.

- Calculating the cost of goods sold (COGS). The perpetual inventory software uses the most up-to-date inventory levels to calculate the COGS for each transaction.

- Updating inventory records. The perpetual inventory system automatically updates the inventory records so inventory levels are always accurate.

- Adjusting reorder points. The system also uses historical data to adjust inventory as sales increase or decrease throughout the year and across seasons.

- Conducting regular physical inventory counts. A perpetual inventory system is very accurate. Still, it’s important to do regular physical inventory counts to verify the accuracy of the inventory records and detect any discrepancies or errors.

These steps help businesses stay on top of their inventory and determine their inventory’s cost flow.

Perpetual inventory system formula

We’ll explain the perpetual inventory system using the formula below.

Put away the calculator — you don’t have to be Einstein to work this one out.

Beginning Inventory + Receipts - Shipments = Ending Inventory

- Beginning inventory. This relates to the quantity of inventory your business has at the beginning of a specific period. The system will update this as you sell goods throughout the accounting period.

- Receipts. This refers to the number of products sold. Every time you get a product from the supplier, the system records it and adds it to the inventory count in real time.

- Shipments. Shipments simply refer to what you’ve sold or shipped over that period. When you sell an item, the system deducts it from the inventory.

- Ending inventory. Ending inventory is what’s leftover from the beginning inventory and receipts after the system calculates the items bought.

In very basic terms, let’s say you have 100 bottles of lemonade (beginning inventory)🍋.

You get a delivery from a supplier who adds 15 more bottles (receipts) to your inventory account.

100 + 15 = 115

Now, you have 115 bottles of lemonade.

100 + 15 - 50 = 65

If customers bought 50 bottles (shipments), your ending inventory would be 65 bottles of lemonade at the end of the period 💸.

Of course, this is in very simple terms.

However, a perpetual inventory system tracks complex businesses dealing with high inventory levels (like a fast-food chain).

An example of the perpetual inventory system

Let’s say there’s a grocery store called Circuit for Groceries 😊.

It manages a high stock inventory, and periodic inventory checks are possible but pretty laborious.

Instead, let’s say Circuit for Groceries uses the perpetual inventory system to maintain its amount of inventory.

Each item has a unique barcode that a barcode scanner can read.

When a worker scans the item, they send a signal to the store’s perpetual management system.

This alerts the system that the item has been sold and automatically adjusts the grocery store’s inventory levels.

For example, if a store has 1,000 packs of nacho chips and 800 are sold one busy Saturday afternoon, the perpetual inventory system knows that only 200 nacho chips are left in stock.

The store can then use that information to reorder and replenish its stock, and even use historic data trends to forecast inventory item demand for next Saturday.

This helps reduce the likelihood of nacho chips, or any other stock, selling out completely 🛒.

What are the benefits of using a perpetual inventory system?

Perpetual inventory systems come with a whole host of benefits that make managing large amounts of raw materials and real-time inventory easier.

Let’s look at some benefits of a perpetual inventory system.

Real-time data and inventory tracking

Data is everything these days.

Running a busy store means managing a lot of data related to things like inventory, deliveries, staff, and suppliers.

A great benefit of a perpetual inventory system is that it records data in real time, so you know exactly how much stock you have and when to order more.

It also means you can view it all in one place, making it much more convenient and easier for you and your employees to understand.

Better demand forecasting

Having the ability to forecast demand is a superpower ⚡.

Because the perpetual inventory system collects data, it can also forecast demand quickly and simply.

This means you know exactly when to order more products.

You also have the ability to know if a busy season is approaching and what the demand will be like for seasonal items.

For example, there might be an uptick in the number of grills sold in the summer.

Luckily for you, your perpetual accounting system can let you know ahead of time when it’ll be sizzling ☀️.

Reduced inventory management costs

Managing a ton of items is a chore — a costly one.

Storing produce can be expensive, especially with items like milk, frozen meat, or eggs needing pricey refrigeration.

With updates in real time, a perpetual inventory management system can control and minimize holding costs and stockouts.

Since merchandise inventory systems automate many manual processes (like physically taking notes in a journal or adding data to a spreadsheet), they can save on labor costs, too.

It also means employees no longer need to do cycle counting, saving more time and labor.

This gives your employees more time to focus on customer service without worrying about stock levels and other inventory information.

Creates a paper trail

In business, everything needs a paper trail. People leave jobs, tax inspectors arrive, and you need to keep track of everything.

Fortunately, your inventory management system tracks inventory movements throughout the supply chain to optimize, forecast, and let you know what’s in stock or out.

This helps you keep track of everything that’s happening to your products.

Ease of preparing financial reports

The perpetual inventory method can speed up the preparation of your financial reports through record-keeping and keeping track of inventory for you.

This means you don’t have to rely on reading time-consuming journal entries and poring through accounting records.

Inventory management software can help you understand your gross profit, avoid calculation errors, and estimate your inventory valuation (so you know exactly what it’s worth).

It can also help you avoid the boring donkey work of preparing financial statements, balance sheets, and income statements.

Perpetual vs. periodic inventory systems

Perpetual inventory systems immediately track items at the point of sale.

This lets you know exactly when your business sells an item and how much of that product you have left — and that information is easily accessible in real time.

On the other hand, periodic inventory systems involve physically counting an item to determine whether it’s been sold.

Here are some of the other main distinctions between the two:

- Bigger businesses typically use perpetual inventory systems since they have more inventory to track.

- Perpetual inventory systems involve less effort once they’re set up, whereas periodic inventory needs consistent work each time a stock take happens.

- There’s a larger margin for error in periodic inventory compared to perpetual inventory systems, meaning higher inventory costs and inventory control costs (making sure you have enough of the right product).

- Periodic inventory does have a slight edge over perpetual inventory systems when it comes to assessing breakage. Physical checks can assess damage more frequently than tracking via the perpetual inventory and other point-of-sale systems.

When does it make sense to use a perpetual inventory system?

Whether using a perpetual inventory system makes sense really depends on your business.

Large enterprises managing a large number of products typically use perpetual inventory systems, like grocery stores or fast-food chains.

Businesses managing a smaller amount of stock usually use the periodic method.

So, if you’re a small business, it might not be worth spending the extra money to install a perpetual inventory system.

However, companies that do invest in a perpetual inventory system can reap the rewards later. They spend less time taking stock, have lower labor costs, and are more efficient.

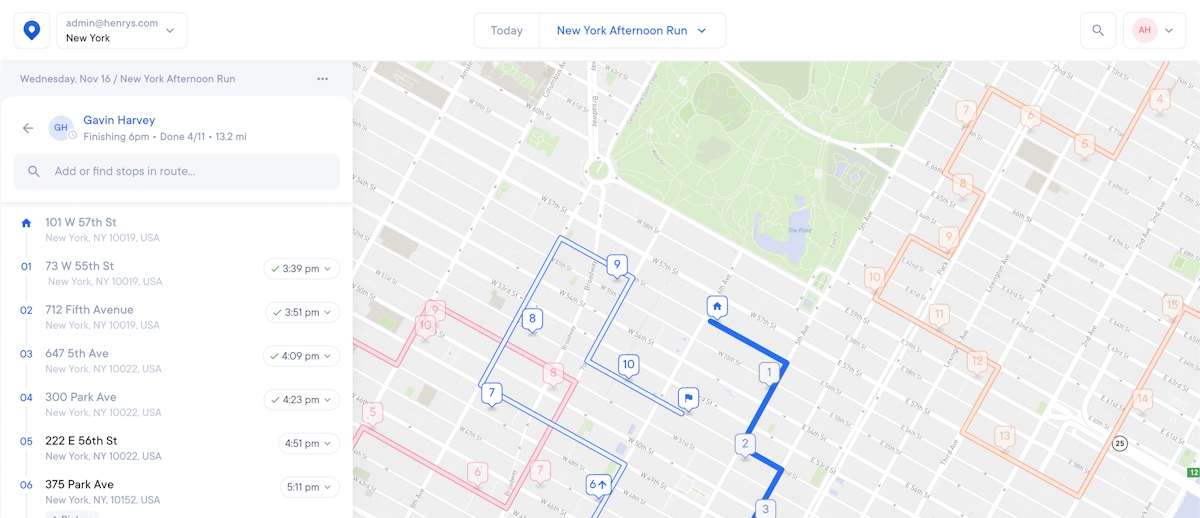

Circuit for Teams helps businesses ship products

A perpetual inventory system is a great idea for managing inventory.

It’s efficient, convenient, and helps inform future decision-making through forecasting.

But it doesn’t matter how organized your inventory is — you must also get items out to customers.

That’s where Circuit for Teams comes in, helping you deliver packages with confidence.

On top of finding the fastest and most efficient routes for your drivers, Circuit for Teams allows you to create and distribute multiple routes for different drivers in minutes.

You can also add multiple depots to the Circuit for Teams software. Your administrators can choose to display activity from all their depots or just one.