Middle-Mile Logistics: The Complete Guide

An efficient and economical middle-mile logistics process can give your business a competitive edge. Learn how in this comprehensive guide.

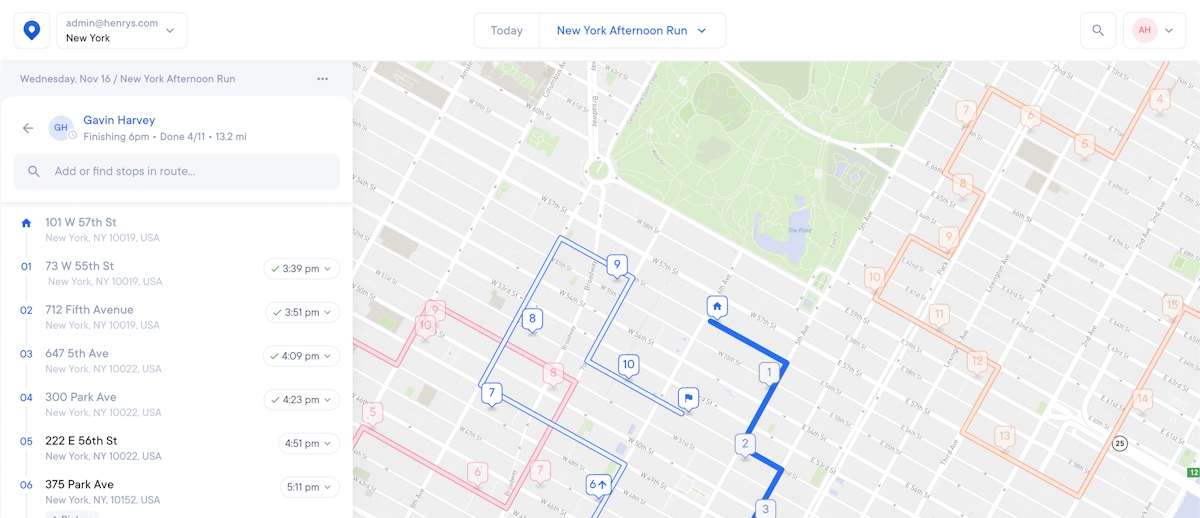

Use Circuit for Teams to improve your middle-mile logistics with optimized route planning and real-time driver tracking.

Have you ever been on a road trip and heard someone say something like, “Getting there is half the fun?” If that resonates with you, allow me to introduce you to middle-mile logistics!

Middle-mile logistics encompass everything that happens between where your load starts and where it’s going. It’s like your inventory’s road trip.

Have questions about middle-mile logistics? That’s why I’m here.

I’ll walk you through everything you need to know about middle-mile logistics in this article. I’ll also make you aware of the most common challenges and how to improve your middle-mile operations.

Key takeaways

- Middle-mile logistics is what happens to your items when moving between the first warehouse or storage unit to the next holding location.

- Addressing middle-mile logistics is a great way to improve delivery efficiency and avoid potential delays.

- Poor route optimization and outdated technology are two of the top challenges for middle-mile logistics management.

- You can improve middle-mile logistics by planning the best routes, using telematics, optimizing shipping processes, and improving your inventory system.

What is middle-mile logistics?

Imagine you buy a new putter in hopes of shaving a few strokes off your golf game. Best of luck, by the way — I’m still looking for my shot in this forest and hoping my friends don’t see me throw another ball back into the fairway.

Before buying your putter, it was made at a production center and shipped to a warehouse or distribution center, where it was held until it was shipped to the fulfillment facility or retail store where you bought it.

Middle-mile logistics are what happens to your putter between the first and second destination. Since there are a lot of moving parts, it takes time and energy to make sure your putter stays safe and arrives on time as it journeys from the distribution center to the fulfillment center.

First-mile vs. middle-mile vs. last-mile logistics

There are several key differences between first-mile, middle-mile, and last-mile logistics, but each component is a key piece of the supply chain process.

Yeah, it’s a lot to remember. But this section is important, and you’ll soon see that keeping up with first-mile, middle-mile, and last-mile delivery is not as tricky as you thought.

First-mile logistics

Remember how your putter started at a production center and shipped to the first warehouse afterward?

That trip’s details were part of the putter’s first-mile logistics. While it’s still early in the process, this part must go well to make sure the rest of the journey goes off without a hitch.

Middle-mile logistics

Middle-mile delivery is unique in the shipping process. The items have already moved on from the production center but aren’t quite ready to head to the customer. They sit in a warehouse until that time comes.

What makes middle-mile logistics so important is that bottlenecks can happen there, causing customers to get late deliveries. Improving middle-mile delivery and operations can prevent delays and keep customers satisfied.

Last-mile logistics

Hey Alexa, play “The Final Countdown” by Europe!

Last-mile logistics happen when the item is en route from the second warehouse or holding center to the customer. Likewise, last-mile delivery is the final stage of distribution.

When we talk about last-mile logistics, we’re concerned with making a quick, accurate, and affordable customer delivery that meets expectations.

The importance of middle-mile logistics

So, that’s how middle-mile logistics fit into the full picture. Now, I’ll get into more detail about why this all matters.

We live in a world where fast and efficient delivery is becoming more and more important. Many logistics companies offer same-day delivery — so many that customers are beginning to expect it.

This means anything you can do to give yourself a leg up on the competition can be the secret sauce that pushes your business to the top.

If you find ways to improve your middle-mile delivery, you’ll be well-prepared to lap the companies that are simply maintaining the status quo and not thinking about how to improve their efficiency.

While middle-mile innovations can be tough to identify in a well-established system, looking at your current delivery operations and thinking about how to improve them is still important.

In the next few sections, I’ll give you a deeper look at the benefits and challenges of taking your middle-mile logistics to the next level.

Common middle-mile logistics challenges

Middle-mile logistics are important, but making changes isn’t usually a walk in the park. Here are some of the most common challenges companies face when addressing their middle-mile delivery:

- Poor warehouse visibility: Have you ever been inside a warehouse? They are crazy big and full of stuff, especially when your boss comes in and decides to host an Inventory luau. Even if Michael Scott isn’t your boss, losing items or developing inventory discrepancies can still happen. This is why warehouse visibility matters so much.

- Inefficient routes: There are so many reasons companies might have inefficient delivery routes. Maybe they haven’t reassessed their routes since 1995, or perhaps they are wasting time and money sitting in traffic. Either way, unaddressed route inefficiencies can prove challenging for middle-mile logistics.

- Lack of technology: Some warehouses still use the same routes they developed 30 years ago. Others are still running Windows 95 and calling Circuit City or Radio Shack for their supplies. One thing that may help is if you join the rest of us in the future and use modern technology to improve your delivery operations.

Four tips to improve your middle-mile logistics process

We’ve established that middle-mile logistics are important and have plenty of time-saving and cost-effective benefits, which is a good start to the conversation.

Before I finish up, I want you to think about how to improve your logistics management process. Hopefully, you’ll find a few actionable steps you can implement right away.

1. Use route optimization software

Sitting in traffic is a terrible use of time and money and can prevent customers from getting their deliveries on time — not a good outcome for anyone involved.

Cut down on wasted resources and increase your number of successful on-time deliveries by utilizing route management software like Circuit for Teams.

Just plug in your list of trucker or driver delivery stops, and Circuit for Teams creates optimized routes that take the least amount of time and fuel.

In addition to optimizing your delivery routes, Circuit for Teams offers real-time delivery notifications and ETAs so your customers know exactly when to expect their delivery.

2. Utilize an effective warehouse management system

Implementing an effective warehouse management system is another way to improve mid-mile logistics. Even though it doesn’t directly connect to the transportation of goods, it can still positively impact your middle-mile transportation.

A poor inventory management system is one of the most common warehousing mistakes. You already learned that mismanaging inventory can harm middle-mile logistics because it paints an inaccurate picture of how much supply you actually have on hand.

3. Optimize your shipping and receiving process

If your shipping and delivery processes run smoothly, your middle-mile logistics will be more efficient and streamlined. This means that the movement of goods from one warehouse to another happens as fast as possible.

This helps you minimize delays and cut transit times. This enhances your mid-mile operations and makes inventory easier to manage because you won’t have to worry about accounting for a large amount of pipeline inventory.

4. Track deliveries with telematics

Delivery managers can use telematics to track their drivers in real time. Rather than wondering where your drivers are or when they should return, you can monitor their current location, speed, and fuel efficiency.

Use these insights to improve the customer experience while limiting fuel consumption and enjoying other cost-saving benefits, like less vehicle maintenance. Some of your in-house vehicles may already have built-in telematics capabilities, while others might need a special telematics plug-in.

Discover how Circuit for Teams can streamline your delivery operations

Middle-mile logistics are important, but managing and improving them doesn’t have to cause major headaches. If you implement a few of the tips you learned in this article and pay attention to the data you collect as a result, you’ll be well on your way to streamlining your business and improving your operations.

Another step to consider is trying out Circuit for Teams.

This delivery management software constantly works to optimize your delivery routes so you never waste unnecessary time, money, or vehicle wear and tear. And since efficient routes mean timely deliveries, Circuit for Teams also lets you serve more customers in less time.

Give Circuit for Teams a try for free today!