What Is Pipeline Inventory & How Do You Manage It?

Learn how pipeline inventory impacts your business and discover the best tips to manage it effectively.

Use Circuit for Teams to enhance your inventory management with successful on-time deliveries.

Ever heard someone say something is “in the pipeline?” That phrase might make you imagine something is on its way, but it isn’t quite here yet.

That’s basically what we mean when we say “pipeline inventory.” Your pipeline inventory includes any goods or materials you’ve ordered from a supplier that are not physically in your possession yet.

Your pipeline stock might be composed of future product lines, or it could just mean you’ll be replenishing or replacing your current supply soon. Either way, it refers to any in-transit inventory that’s on its way to you.

Knowing how pipeline inventory works and how to properly manage it can have tremendous benefits for your manufacturing process or supply chain management strategies. In this article, you’ll learn more about what pipeline inventory is and how to effectively manage your pipeline stock.

Key takeaways

- Pipeline inventory refers to any goods or materials you’ve paid for that are still in transit to you.

- Properly managing and tracking pipeline inventory helps you plan for supply chain contingencies, delays, and potential disruptions. That’s because it completes the picture of your overall stock levels so you can use and plan your resources efficiently, making timely adjustments as needed.

- The formula to determine pipeline inventory is Lead time x Demand rate = Pipeline inventory.

- You can manage pipeline inventory by accurately tracking delivery locations, keeping safety stockon hand, and improving your inventory forecasting.

How does pipeline inventory work?

Pipeline inventory matters because it tracks part of your assets. Although you might not have gotten the inventory, you paid for it, so you own it.

This makes it a little different from any raw materials you’ve bought to create finished products. Those are considered part of your “work-in-progress” inventory.

Most businesses have a process for keeping up with their pipeline inventory, especially if they consistently sell the amount of inventory they keep on hand. They use stats like warehouse receiving times and production lead lines to account for their ongoing and future needs.

The larger your business, the tougher it is to track the amount of pipeline inventory you need. You’ll also have to plan for more contingencies, delays, and slowdowns.

Accounting practices for pipeline inventory

Record the value of your pipeline inventory on your company balance sheet for accounting purposes. This is important because your pipeline inventory is a company asset and should be part of your bookkeeping.

Otherwise, it’s easy to lose track of how much inventory your company actually has. “Out of sight, out of mind” may work in some settings, but not with inventory.

What is decoupling inventory?

Decoupling inventory (sometimes called decoupling stock) means setting aside finished inventory or raw materials to prevent supply shortages or deadstock situations. This protects you from a slowed supply chain or production process due to one missing piece.

It’s like if you were building a Lego set and realized you were out of a certain necessary piece. Maybe you miscounted what you needed for that specific creation or thought something came with the set, but it didn’t.

If you have decoupling inventory available, you have more on hand than you thought you needed — meaning you can just pull the needed piece from that surplus.

Pipeline inventory formula

OK, so that’s how pipeline inventory works and how it can help your business. Now, you’re probably wondering how to determine the value of your company’s inventory in the pipeline for accounting purposes. We can help with that, too.

Let’s look at the simple formula you can use to calculate your pipeline inventory, plus an example to clarify how you can use it. This formula can also help you manage carrying costs and inventory costs.

Lead time x Demand rate = Pipeline inventory

By multiplying the lead time (the time it takes for your inventory to be delivered after you order it) by the demand rate (the rate at which your inventory is being used or sold), you get an estimate of the average amount of inventory that should be in the pipeline at a given time.

Let’s further break down each piece of the formula:

- Lead time: This is how long your supplier takes to deliver the goods to you.

- Demand rate: This is how many items you’re selling. It is typically measured in units per day, week, month, or any other relevant time period, depending on the context and your industry.

- Pipeline inventory: Once you determine the lead time and demand rate, you can solve the equation to calculate your pipeline inventory. This figure signifies the amount of inventory needed to meet demand during the time period you defined when you calculated the demand rate (in a day, week, month, etc.)

Once you solve the equation, you’ll also understand how much your pipeline inventory is worth and can adjust your books accordingly.

As you can see, long lead times and disruptions or changes in demand can impact the amount of pipeline inventory you should have on hand.

Example pipeline inventory calculation

Let’s take a look at a real-life pipeline inventory example to make this super-duper easy to understand.

Imagine you sell plastic trash cans. It normally takes around two weeks for a shipment to arrive from your supplier, and you typically sell 50 trash cans per week at $20 each.

Knowing this, you can calculate your pipeline inventory in a given week and its value. Let’s plug these numbers into our equation from above:

Lead time (2 weeks) x Demand rate (50 trash cans per week) = Pipeline inventory (100 trash cans per week)

There you have it! You have a pipeline inventory of 100 trash cans in a given week. This means you would expect to have 100 trash cans in transit or awaiting delivery at any given time, accounting for the two-week lead time and the weekly demand rate of 50 trash cans.

Five tips for pipeline inventory management

So, there’s a comprehensive overview of how pipeline inventory management works. Before we wrap up, let’s see how you can improve your pipeline inventory management to protect your business and streamline operations anytime a portion of your inventory level is en route.

Track inventory location

If you can determine how to keep ongoing track of your inventory, you can better grasp how much pipeline inventory you have (or if you need more).

Some people do this with a spreadsheet, where they might list expected delivery and lead times on the same document. This can take some time, depending on the size of your operation.

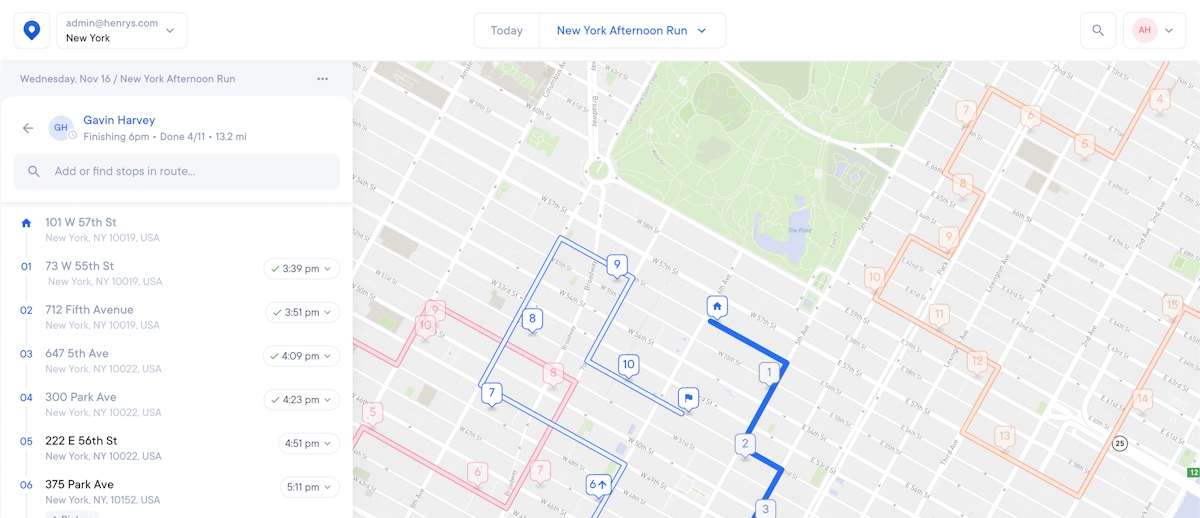

Another option is to use automated inventory management software to track your ongoing inventory, including any pipeline inventory still on its way.

Use inventory forecasting

Until you forecast your inventory, you won’t know exactly how much you need. Real-time data takes the guesswork out of the equation so you can develop an accurate understanding of the amount you should have on hand, how much should be on its way to you, and how much you should order (if any).

You can run these numbers by hand, but it’s much easier to use automated inventory management software to forecast how much supply you need.

One way inventory forecasting works is by telling you which inventory is likely to move slowly and what will sell fast (so you know what materials to buy more of and when).

Have safety stock

Safety stock is a type of inventory that acts as a cushion against potential stockouts. It’s a great contingency plan in the event of a stoppage in supply or an issue with a wholesaler.

If you see a sudden increase in demand due to business seasonality or because a celebrity was spotted using your product, having safety stock on hand will help you continue meeting customer demand.

It helps with pipeline inventory management by protecting you from delayed or damaged shipments. If you choose to have safety stock, it’s important to determine what stock level is too much so you can avoid excess holding costs and shelf life issues.

Use a real-time inventory management system

A good inventory management system tracks your entire inventory in real time so you always know how much inventory you have and where it is. That includes your pipeline inventory and in-transit customer orders, all the way through to last-mile delivery.

Managing your own deliveries? Circuit for Teams streamlines the process

Although pipeline inventory is not part of your on-hand inventory yet (what you have ready to ship out for customers), keeping an accurate count is important.

Tracking and monitoring your pipeline inventory in real time helps you know how much supply you have available, how much you’ve spent on it, and what you might need to order if that total is not enough to meet demand.

But it’s still just one cog in the inventory management machine. You must also track customer deliveries, which is where Circuit for Teams can help.

One of its key features for streamlining your last-mile deliveries is optimizing driver routes to cut down wasted time, energy, and fuel costs. You can also use it to send your customers notifications when their deliveries are en route and when they’ve been delivered, keeping them informed and happy.

Try Circuit for Teams for free today and help your drivers get more done in less time and with fewer resources.