What Is a Distribution Center?

A distribution center offers order fulfillment services to eCommerce businesses. Learn how it helps with the logistics process and redistribution of goods.

Optimize delivery from your distribution center by managing drivers and deliveries using Circuit for Teams.

As a business owner, handling orders and warehousing can be a lot.

There’s so much to do!

From packing to sorting to shipping, all these tasks can eat into your time and money.

But there’s a way out: You can use a distribution center to help you with order fulfillment.

Distribution centers serve as a go-between in the supply chain — in other words, they act as a bridge between the supplier and the customer.

This means they might oversee everything from receiving products from the supplier to getting those products into customers’ hands.

If you own an eCommerce business, you can work with a distribution center to optimize your shipping process.

With a distribution center, you don’t have to worry about storing, shipping, or redistributing goods. The center will take care of that for you.

You don’t have to waste time and effort on shipping processes. Instead, you can dedicate those resources to other aspects of your business.

By working with a distribution center, you can offer better shipping services to your customers — resulting in higher customer satisfaction.

To help you decide if it’s right for you, I’ll explain how a distribution center works and how you can use one based on your business needs.

What does a distribution center do?

In a nutshell, a distribution center stores, packs, and ships goods that your company produces.

The process at a typical distribution center looks like this:

- The distribution center receives the goods from your supplier.

- The center stores these goods — usually for a short period — until they’re ready to be packed and shipped.

- Once they’re packed, the center handles the shipping process. The packages are delivered to their final destinations.

Shipping logistics are probably a key part of your eCommerce business.

And deliveries are hard — we get it!

Outsourcing deliveries to a distribution center can be one way to make sure they get done as fast as possible.

This is because distribution centers tend to be located close to cities and residential areas. This helps in reducing delivery time and distance.

Once the center receives the product, employees can package the order and deliver it to its final destination (the customer).

Besides delivery time, a distribution center can also help you with shipping costs.

Let’s say you own a direct-to-consumer (D2C) business that sells clothes to customers.

Your main warehouses — where you store all your products — are located in San Francisco and Oakland, California. Most of your orders are shipped to Los Angeles, California.

If you ship all your packages to the final delivery point from the main warehouses, your transportation costs will be high.

As you’ll have to ship each package separately, you’ll pay shipping costs for every product.

But with a distribution center located in Los Angeles, you’ll have a central fulfillment center. You can bulk deliver all your products.

The LA distribution center can separate the packages for last-mile delivery — much shorter than if you had shipped your products from San Francisco.

Another advantage of working with a distribution center is service quality.

A distribution center will complete deliveries within the given time frame.

This can help your business meet customer demand and offer a better shopping experience.

How a typical distribution center works

Now that you know the benefits of using a distribution center for your eCommerce business, you might be considering working with one.

But before that, it’s important to understand how a distribution center works.

The first step in distribution center logistics is receiving products from the supplier.

Warehouse workers receive and sort these products.

Once distribution center employees sort the packages, they put the products away.

Distribution centers are usually located closer to residential areas.

This helps them get products to their final destination more quickly.

So, products are often stored at the distribution center only for a short period — not more than a few weeks.

After storage comes the packing stage.

Here, the products are packaged for safe shipping. Employees use the right packaging materials and methods when getting your products ready for delivery.

Once employees package the products, they ready them for shipment to the customer.

In the final stage, the delivery person picks up the packages and takes them to their final destinations.

This last leg of shipping logistics is called last-mile delivery (making sure your product reaches the customer).

Distribution centers vary in size depending on the type and number of businesses the center serves.

Some centers work for a large number of companies or manage high shipment volumes. They need more space for inventory storage and order management.

For example, while FedEx has a distribution center that’s over 132,000 square feet, Amazon distribution centers can be as big as 800,000 square feet. Blows your mind, right?

The size of the distribution center also depends on the type of equipment and storage methods used.

Consider a distribution center that caters to businesses selling food products.

They’ll need many industrial refrigerators and freezers. This means they’ll need more space compared to centers that don’t need this kind of equipment.

Depending on the capacity of the distribution centers, they may take on other processes.

Many distribution centers offer reverse logistics to eCommerce businesses. This means the center will handle the returns for your business.

A distribution center may also offer restocking services. This means they’ll forecast demand and work on inventory replenishment.

Distribution centers use the most advanced technology and methods to streamline the distribution network. This includes everything from receiving goods to the last-mile delivery process.

Some of the most common technologies distribution centers use include:

Automated tools

Automated tools help with the loading and unloading of items from transportation vehicles.

These tools are especially helpful for distribution centers dealing with large and heavy items. These machines make manual processes easier and faster.

Automated guided vehicles (AGV)

Distribution centers are huge, and transporting goods from one part of the warehouse to the other can be time-consuming. Many centers have automated guided vehicles to get goods from one place to another.

AGVs use GPS to complete transportation tasks in very little time.

Warehouse management systems (WMS)

Most distribution centers use these systems to assist with things like warehouse design, inventory tracking, shipping tracking, labor management, yard and dock management, and reporting.

Inventory control platforms

Inventory control platforms let distribution centers have complete control over inventory management.

Some of the most popular inventory control systems warehouses use include:

- ABC Inventory Control System

- Three-Bin System

- Just-in-Time (JIT) System

- Outsourcing Inventory System

- Computerized Inventory Control System

- Fixed Order Quantity

- Fixed Period Ordering

Collaborative robots

Collaborative robots, or cobots, are built to work safely alongside human workers. Cobots interact with workers in a shared workspace to complete tasks. They are different from automated tools and AGVs that work independently.

Most distribution centers use cobots because they’re multifunctional. They’re also easy to set up, operate, and scale.

Automated storage and retrieval systems (AS/RS)

Automated storage and retrieval systems automatically retrieve and place items from a pickup point to a drop-off location.

These systems manage tasks with precision, accuracy, and speed. They can be computer-controlled, meaning they don’t need human interference during tasks.

Different distribution centers have different needs. They may use a few or all of these technologies to optimize their order fulfillment processes.

Besides automation, distribution centers also use different types of shipping and packing materials.

These include intermodal containers, pallets, bulk boxes, cases and cartons, and totes.

- Intermodal containers are also called shipping containers. They help in the transportation of goods over long distances. These containers can be used across various modes of transport, making them an ideal choice for distribution centers.

- Pallets are rigid and portable structures used to carry and move heavy loads with ease. They’re designed to keep the goods stable when lifted by a pallet jack or a forklift.

- Cases, cartons, and bulk boxes come in various sizes, shapes, and strengths. A distribution center chooses which box to use depending on the shipment’s size, dimensions, weight, and fragility.

What types of businesses use distribution centers?

Many businesses use distribution centers to streamline their shipping logistics.

Some of the most well-known businesses have upped their delivery game by working with distribution centers.

Amazon, for instance, has over 1,100 fulfillment centers of various types in the US.

And in 2022, Amazon was able to expand its same-day delivery service to more brands.

Amazon ships about 1.6 million packages a day in the US alone — that’s a huge number!

So, how does Amazon manage to ship all these packages?

Hint: because of their distribution centers.

Amazon has many distribution centers in residential areas spread across the country. This helps them bring products to their customers quickly and efficiently.

Walmart is another business that has taken advantage of distribution centers.

Walmart has 210 distribution centers across the country. These are the hubs of activity for their business.

Walmart’s distribution centers ship general merchandise and dry groceries to customers daily.

Each distribution center is more than 1 million square feet in size. This allows them to offer products to roughly 100 stores.

Walmart also has six disaster distribution centers across the country. These are stocked to offer rapid response in case of emergencies.

IKEA is another business whose success is heavily dependent on its distribution centers.

Although IKEA is known for its warehouse-sized showrooms, about 11 percent of its sales are online. Its eCommerce strategy involves giving customers an excellent delivery experience.

When you place an order on IKEA’s website, the products are shipped from the stock holding location closest to your ZIP code. This helps them maintain an efficient delivery service with quick turnaround times.

About distribution centers owned by third-party logistics companies

Besides a few eCommerce giants, most eCommerce businesses don’t have their own distribution centers.

After all, owning and managing a distribution center can be an expensive affair.

So, who owns and operates distribution centers? The answer is third-party logistics companies.

Third-party logistics companies (3PL) offer supply chain management and shipping services to eCommerce businesses.

These companies offer logistics services to other companies.

For example, a small-scale candle business may not have the resources or bandwidth to own a distribution center.

And shipping individual orders to different parts of the country might eat into the company’s bottom line.

So, how can such a business ship orders while making a profit?

By using third-party logistics companies to streamline and handle their shipping process for them.

The third-party logistics company will receive their products and store and pack them. Then, they’ll deliver these packages to the final destination.

If you own an eCommerce business, you might consider using a third-party logistics solution. They can be valuable in optimizing your delivery process.

They can identify and fill gaps in the supply chain, give you access to skilled labor and advanced equipment, and help you scale your business.

When choosing a third-party logistics company, consider a few factors before making your choice.

After all, you only want the best solution for your eCommerce business.

First, consider the track record of the third-party logistics company.

Remember that having high-quality products isn’t always enough. The delivery experience will also reflect on your company.

And when you choose a third-party logistics solution, you’re putting your reputation into their hands.

So, you need to pick one you can trust to meet your and your customers’ needs.

Look for a third-party logistics company with a positive track record. They’ll be more likely to offer you a high-quality logistics solution.

The company will handle your products carefully and make sure that it reaches the customer within the specified time frame.

And as your business grows, the logistics company should be able to keep up with the increase in demand.

After checking the company’s track record and scalability, assess the types of solutions offered and check whether they meet your business needs.

Suppose your eCommerce business sells food items.

You’ll want to work with a 3PL company that offers solutions like temperature-controlled storage.

If you deal with products that need to be delivered within a very short time frame, you’ll need to hire a third-party logistics company that can quickly move your products to customers.

Also, it’s important to understand the technology used in their solutions.

Make sure to ask the third-party logistics company to walk you through its processes before making a decision.

When choosing a third-party logistics company, you also need to check its pricing.

- How much does the company charge?

- Does it charge per package? Or does it charge on a monthly basis?

- What are its storage fees?

- What are its delivery fees?

Once you understand the fee structure, compare it to your business’s profitability.

If you hire a particular third-party logistics company, will you still be able to make a decent profit?

The location of the 3PL’s distribution centers is just as important.

Yes, you need a center that’s close to where you receive the bulk of customer orders.

At the same time, you need that center to be close to your supplies.

A shorter distance will help you get your final products to the center quickly — saving you time and money.

Lastly, look at the third-party logistics company’s experience. Working with a company with years of industry experience has its benefits.

If the company has been in business for a long time, it’ll likely have a grip on overcoming obstacles and hurdles.

By keeping all these factors in mind, you can make an informed choice and work with a third-party logistics company that best suits your needs.

What is the difference between a warehouse and a distribution center?

Warehouses and distribution centers offer similar services. This makes it easy to mistake one for another.

But warehouses and distribution centers are not the same. They have different uses and functions, including:

- Warehouse facilities store inventory. In contrast, distribution centers offer other services besides storage.

- Warehouses don’t offer order processing or order fulfillment solutions. Distribution centers help with order fulfillment by offering services like packing and shipping.

- Businesses use warehouses to store products until needed. Most distribution centers only receive, store, and ship ordered products. However, some distribution centers may place a preorder for products by forecasting demand.

- Traditional warehouses have a slow flow rate and store products for a longer period. In contrast, products move through distribution centers very quickly.

- Businesses store goods in warehouses between supply chain processes. Warehouses only deal with businesses, not customers. But distribution centers deal with businesses and customers during different stages.

- Warehouse operations are less complex since warehouses only offer storage services. Operations at distribution centers are more intricate. This is because they manage most processes related to order management.

Traditional warehouses and distribution centers serve different functions. But they’re both essential parts of the supply management system.

As a business owner, it’s important to think about your needs. This can help you decide whether to use warehouses or distribution centers (or both).

While warehouses offer storage options, distribution centers can offer efficiency in operations.

For example, if your business is large and has bulk shipments to deliver, managing inventory and keeping track of your orders might be difficult.

In this case, it might make more sense to work with a distribution center. A distribution center will handle the process on your behalf and offer end-to-end solutions.

Are distribution centers typically used for certain kinds of goods?

Most retail businesses can use and benefit from distribution centers.

After all, almost every business can enjoy the efficiency these centers offer.

Distribution centers are especially suited for businesses that need a fast flow of goods.

For example, if your business produces or supplies perishable goods (like food items), your products need to reach customers quickly. No one wants moldy goods!

Working with a distribution center can help with the efficient delivery of products.

Most modern customers expect faster and cheaper shipping than in years past.

How can you achieve that? By using a distribution center to optimize your delivery process.

A distribution center can give your customers an elevated delivery experience by offering two- or even same-day delivery.

Offering same-day delivery, in particular, can help you increase your conversion rate and sales.

A great example of this strategy is Amazon Prime, which guarantees its customers one-day delivery.

Amazon’s delivery speed is one of the principal reasons for the business’s success.

If your business deals with groceries, pharmaceuticals, food products, and other items that need one-day delivery, consider working with a distribution center to make your order fulfillment process more efficient.

Should you use a distribution center for your business?

If you have an eCommerce business, it can be beneficial to use a distribution center.

With a distribution center, you don’t have to waste time designing an order management system for your business.

The center will manage every aspect of order fulfillment for you.

The distribution center will receive and store your orders for you.

And most distribution centers have a high storage capacity. This means they’ll be able to offer you plenty of space to store your inventory.

The distribution center will even receive orders for you.

So, all you have to do is ship your products from your manufacturing facility to the distribution center.

Once your products are received, the distribution center will pack the items.

As a business, you can pack your products before shipping them to the center (if you have the time and resources).

However, an experienced distribution center will deal with different types of products. They’ll know how to pack the products in the best way possible.

So, if you’re unsure of how to package your products, you can leave it to the distribution center to do that for you.

Once your products are packed, they’ll be shipped to their final destinations.

The distribution center will make sure that your products get to the customers in a timely and secure manner.

Depending on the kind of services they offer, distribution centers may also be able to handle returns management for you.

Managing returns can be time-consuming and expensive.

First, you need to pick up the item from the customer. So, you need a delivery driver to drive to the location to pick it up.

Then, you need to handle the warehousing and distribution process the returned item will go through.

At the same time, you need to make sure the returned item doesn’t interfere with daily operations.

This means you need to manage a separate inventory for returns and make sure that there are separate processes to handle it.

A distribution center can take care of this process for you.

Using a distribution center can also be cost-effective.

While you’ll have to pay fulfillment costs when using a distribution center, it’ll still be cheaper because distribution centers are designed to help save on shipping costs.

Since they manage large volumes of orders, they get discounts on everything from packaging material to shipping rates. These discounts are passed down to sellers, saving them money.

Plus, you’ll save time.

Sorting, packing, shipping, and managing other logistics tasks takes time.

Since you don’t have to worry about shipping logistics when working with a distribution center, you can use all your saved time and money to improve other aspects of your business.

How to work with a distribution center

There may come a time when your business grows enough to have a lot of products and you need a bigger storage space.

You might also need more trained staff who can help with order fulfillment at a larger scale.

The next step is to engage the services of a third-party distribution center that works like a logistical hub to receive, manage, store, pack, and deliver your products to customers.

So, what do you need to look for when engaging the services of a distribution center? Here are a few tips:

- Location: Ideally, your distribution center should be located near your manufacturing unit or near locations where most of your orders are delivered. This will help you save on transportation costs between the manufacturer and your distribution center or between your distribution center and your customers’ locations.

- Services: The distribution center you choose should offer all the services you need. If these include receiving goods from the manufacturer directly, integrating with your eCommerce platform to receive new orders, and packing or delivering products, your final choice should tick all these boxes.

- Flexibility: The center should also be able to tailor its processes to suit your needs. For example, if you want to offer your customers scheduled deliveries, the distribution center should be able to work with you to make sure orders are delivered when promised.

Once you know what you’re looking for, you can start visiting centers located in areas you prefer. Based on site visits and conversations with distribution center managers, you can figure out which one is most suitable for your business and offers you the most flexibility.

You’ll also want to consider costs. While a facility that offers the cheapest rent might seem like the most attractive option, you also have to weigh rent against other important factors.

For example, you might pick a center that doesn’t charge too much rent but is located in an isolated part of the city. This means you may spend more money on transportation and fuel costs.

Also, remember to consider taxes, insurance, and utilities before making your choice.

Distribution center conclusion

Outsourcing the processes of inventory storage, packaging, and last-mile shipping to a distribution center can help your business.

The distribution center will take care of everything for you. You only have to get your products from the manufacturing facility to the distribution center.

However, distribution centers may not be the right solution for all businesses. If you’re just starting out or have limited products, you might be better off handling deliveries yourself.

This is where Circuit for Teams can help.

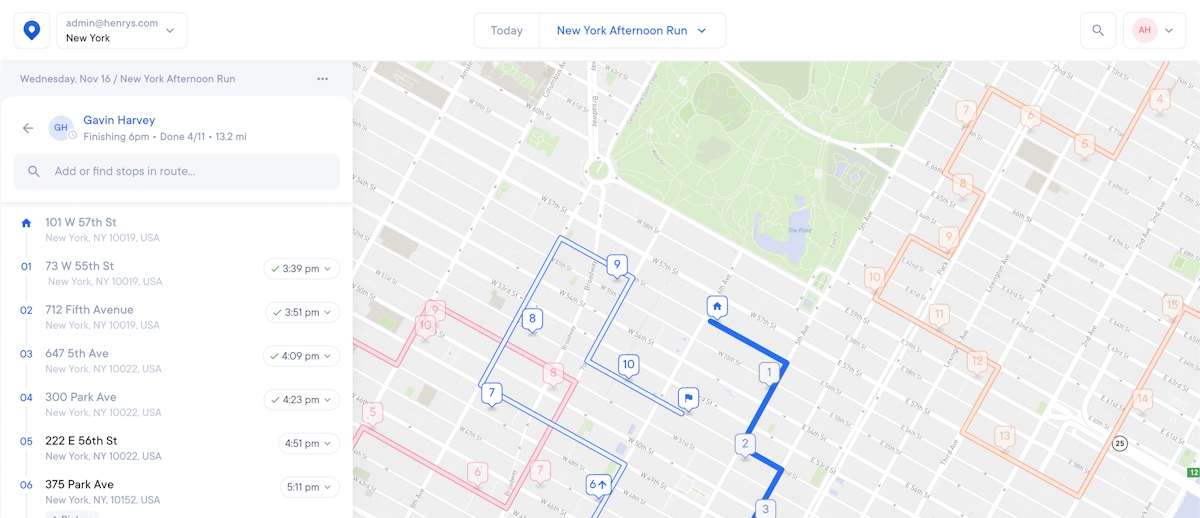

As a route optimization software, Circuit for Teams can help you plan the shortest and most efficient routes for multiple drivers and help you reduce your delivery costs by 20 percent. And when you’re getting your business off the ground, every bit of savings helps.

You can also send customers automatic notifications about the delivery status, so they know exactly when they’ll get their order. Try Circuit for Teams today and see how it can transform your business operations.