Logistics and Supply Chain Abbreviations

Learn the correct definitions for abbreviations in the logistics and supply chain industry so you can keep up with the competition.

Improve your delivery logistics and make more money with Circuit for Teams.

If you work in last-mile delivery, supply chain management, or another logistics business, you probably have to deal with a lot of jargon.

There are plenty of random webpages floating around that offer definitions of various acronyms and abbreviations, but it’s important to have the right definitions for logistics purposes.

If you get caught using the wrong terminology when talking with a customer — yikes.

Their impression of your company might drop.

Get something severely incorrect when deciphering documents, and you risk losing sales to wary customers, or even gaining lawsuits thanks to major business mistakes.

I’ll give you an example.

While “ABC” means one thing in the Alcoholic Beverage Control industry, it means something completely different when working in logistics.

Don’t get lost in “on-screen display” articles when looking up OS&D, and don’t dive into a slang search trying to figure out what JIT means.

I’ve got the meanings you’re looking for here.

With these abbreviations in your back pocket, you can speak the same shortened lingo as your customers and business partners and stay on track toward your money-making goals.

Abbreviations for common logistics documents

These six abbreviations commonly show up in reference to logistics documents.

BOL: Bill of lading

Also known as freight bill or a waybill, the bill of lading (BOL or B/L) is the receipt that a delivery driver gives the recipient when an order is delivered.

It’s a standard document in logistics that serves three main purposes:

- Proof of transportation

- Proof of delivery

- Indication of ownership

BOM: Bill of materials

A bill of materials (BOM) is a common supply chain document that outlines the materials a manufacturer needs to create a specific product.

It’s like a comprehensive shopping list of ingredients.

The BOM document is used by staff — from procurement to inventory management and manufacturing — to keep supply chain operations running smoothly.

This makes sure inventory needs meet product manufacturing demands.

FOB: Free on board or freight on board

Free on board is often shortened as FOB in shipping documents included with cargo shipments being transported overseas.

The term is an official Incoterm (more on that below) that indicates ownership and risk responsibility of the shipment.

As soon as an FOB shipment is loaded onboard and cleared for transport, the shipment is no longer under the responsibility of the seller.

Ownership immediately transfers to the buyer, so if any additional delivery charges come up or the shipment is damaged or lost, the buyer has to deal with those situations.

Incoterms: International commercial Terms

Short for international commercial terms, Incoterms are the standard set of commercial sales terms and definitions that buyers and sellers agree to use during international transactions.

The International Chamber of Commerce (ICC) established these terms to help create a common, voluntary language regarding sales contracts between foreign countries.

Various Incoterms cover definitions for contract obligations, associated expenses, and risks of the transaction (like FOB).

PO: Purchase order

A purchase order (PO) is similar to an invoice with the exception that it’s created by the customer instead of the seller.

The PO serves as a contract offered by the customer when ordering goods before paying for them.

It lists the exact products ordered, quantities, agreed-on pricing, and any other useful details like desired delivery date.

The buyer signs the purchase order to confirm that payment is guaranteed for the PO.

Small businesses often use PO to restock their product inventory.

If you own a local restaurant, for example, you might use purchase orders to request produce deliveries from your fresh produce supplier.

POD: Proof of delivery

Proof of delivery (POD) shows that your delivery company successfully delivered a package to the recipient.

POD records can include the recipient’s signature or a photo of the package left at the address.

Many delivery companies collect electronic proof of delivery, but paper documents are acceptable too.

Learn what you need from your POD software.

Abbreviations for logistics processes

Check out the following abbreviations used in logistics processes, so you’ll know what people are talking about when it comes to the supply chain.

ABC: Activity-based costing

Activity-based costing (ABC) is a method for pricing retail products.

It’s a more precise way of including overhead and manufacturing costs in the price of a product than the more traditional costing method.

Traditional costing uses a generic overhead calculation to apply manufacturing costs to retail prices.

On the other hand, the ABC method involves assigning a specific cost to every activity within the manufacturing process of a product.

Those individual costs then add up to create a unique overhead cost for each product.

API: Application programming interface

When it comes to delivery logistics and supply chain management, an application programming interface (API) is a technology protocol that connects one management system to another.

For example, if you want to allow your warehouse management system (WMS) to share information with your customer relationship management (CRM) software, an API interface allows a smooth, seamless integration.

CRM: Customer relationship management

Companies like eCommerce stores and local retailers use customer relationship management (CRM) software to collect and organize their customer information.

CRMs often help managers access customer contact information, purchase history, email marketing lists, demographics, and other data.

This doesn’t just help you manage online sales. It allows you to do some of these things too:

- Use customer data for marketing campaigns

- Deal with returns and complaints

- Set up personalization for your eCommerce store

- Track analytics

- Integrate other company systems, like your warehouse management system (WMS)

Popular CRM platforms include BigCommerce, Salesforce, Zoho, and HubSpot.

EDI: Electronic data interchange

Electronic data interchange (EDI) systems are protocols that allow computer-to-computer communication.

They’re widely used in logistics and transportation so that businesses and their suppliers can easily exchange shipping documents they both need to reference in their supply chain.

Rather than using email, fax, or other communications that require human feedback, an EDI system creates a direct link between the two companies’ computers, letting both parties send documents directly to the right system in their partner’s computer.

Documents often sent through an EDI system include purchase orders (PO), bills of lading (BOL), invoices, and advance ship notices.

ERP: Enterprise resource planning

Enterprise resource planning (ERP) software can help you run your day-to-day operations.

Leading ERP platforms include NetSuite, Oracle, Microsoft Dynamics, Odoo, and Sage.

Some things that ERPs can help manage include human resources, finances, inventory, manufacturing, customer relationships, and more.

You might integrate other management systems, like warehouse management systems (WMS) and customer relationship management (CRM) software into the ERP using an application programming interface (API).

FIFO: First in, first out

In terms of inventory management, first in, first out (FIFO) is a common method warehouses use to prioritize which items are shipped out first to customers.

FIFO means that the goods purchased or manufactured first are also sold and shipped out first.

FIFO is typically used to manage products that expire or go obsolete over time, like food, makeup, fashion, or electronics.

It’s the practice you see in play in grocery stores, for example, when an employee restocks shelves by placing the new products in the back.

This system allows the oldest products to be picked up by customers first.

Some companies may need to use the opposite method — last in, first out (LIFO). This is sometimes used for products that don’t have an expiration date.

If your company keeps large quantities of stone building materials in your warehouse, for example, you might stack the new inventory on top of the old inventory and ship out new products first.

(Check out our post on the most efficient warehouse layouts for businesses.)

JIT: Just in time

Just-in-time inventory management is a method that aims to schedule deliveries from suppliers just as they’re needed at your warehouse — rather than ordering them too soon and having to store them for a longer time.

When done based on accurate demand forecasting, JIT can help you reduce storage costs and minimize waste of materials that spoil like fresh produce.

MRP: Material requirements planning

Material requirements planning (MRP) is a type of demand forecasting method you can use to manage how you get raw materials for your production processes.

MRP is generally done with software that helps you keep track of current stock levels, customer demand, manufacturing phases, suppliers, and other aspects of the supply chain involved in making sure your company has the raw materials needed to deliver enough products.

RFID: Radio frequency identification

In logistics, radio frequency identification (RFID) is a tracking technology used by companies as an upgraded system from barcode tracking.

Retailers or manufacturers stick RFID tags on products — similar to applying price tags — and use RFID scanners to read those tags.

RFID tags are considered a step above UPC barcodes because they offer more features like more data storage space for product info and the ability to change the information on the tag.

RFID readers can also read multiple RFID tags at once without line of sight, unlike barcode readers.

Learn how you can use RFID with geofencing to improve last-mile delivery.

SKU: Stock keeping unit

A stock keeping unit (SKU) is a unique alphanumeric code that your business might assign to a specific product.

Unlike UPCs (discussed below), SKU systems allow companies to keep track of their inventory in the way that best works for them.

When I worked for a smart home distributor, for example, our SKUs started with a two-letter code that represented the product’s manufacturer, followed by the manufacturer’s part number.

By using a custom system of SKUs like this, your business can more easily search for and identify your usual products.

SCM: Supply chain management

Supply chain management (SCM) is the process of planning and managing the flow of all activities involved in the development of a product or service.

SCM can cover many processes such as getting raw materials or finished products, warehousing, and getting last-mile deliveries to customers.

TMS: Transportation management system

A transportation management system (TMS) is a software platform that can help you manage every aspect of your shipping operations.

Businesses that ship and receive materials regularly typically use a TMS.

A TMS usually helps with everything from vehicle loading and delivery route optimization to package tracking, billing, and analytics reporting.

UPC: Universal product code

A UPC is the combined symbol made up of the barcode and the 12-digit Global Trade Item Number (GTIN) that appears on all retail products.

Official GTINs and their UPCs are given by GS1 US.

This international nonprofit organization sets global barcode standards and maintains barcode systems for the global retail market.

WMS: Warehouse management system

You can use warehouse management system (WMS) software to manage all your inventory and shipping processes.

This type of software typically offers tools to help your warehouse staff receive inventory, unpack and organize stock in the warehouse, pick and pack orders, ship orders, and track inventory throughout its journey.

WMS software also offers an overall view of your company’s inventory for analytics and reporting.

Abbreviations for logistics organizations

There are a lot of specialized organizations in the logistics industry, and these five abbreviations cover the most common terms to know as a logistics pro.

3PL: Third-party logistics provider

When a company wants to outsource any distribution, warehousing, shipping, inventory management, or any other logistics operations, they hire a third-party logistics provider (3PL).

Well-known 3PL service providers include DHL, UPS, and FedEx.

CFS: Container freight station

The acronym CFS stands for container freight station.

CFSs are logistics facilities like large warehouses where cargo is consolidated or separated for the next phase of shipment.

CFS locations are usually near busy shipping centers, such as a water port or a railway center.

FTZ: Free trade zone

Short for free trade zone, or foreign trade zone, an FTZ location is a designated area where cargo can be shipped and handled without payment of customs duties or fees.

Popular international FTZs include Shanghai and Guangdong in China.

There are also many FTZ warehouses in the United States where shippers can import goods and save on tariff costs.

ISO: International Standards Organization

The ISO is the International Standards Organization, a global independent organization that develops standards for technology and manufacturing processes.

While following ISO standards is voluntary, third-party logistics providers (3PL) and other shipping companies can meet these standards and earn ISO certification and prove their commitment to quality service.

NVOCC: Non-vessel operating common carrier

A non-vessel operating common carrier (NVOCC) refers to a freight shipping company that organizes shipments and uses its own bill of lading (BOL) but uses another organization’s ships — never its own vessels.

NVOCCs traditionally refer to carriers dealing with ocean vessels, but some NVOCC providers serve as a one-stop shop for customers who need a complete shipping solution that involves rail, road, and ocean.

Other common logistics and supply chain abbreviations to know

Below are more popular abbreviations that might pop up while you’re working in logistics or supply chain operations.

ETA: Estimated time of arrival

Estimated time of arrival (ETA) indicates when a delivery or person is expected to arrive at the intended destination.

In logistics, ETAs are often carefully calculated based on a range of real-time factors, like the driver’s scheduled route, traffic conditions, weather, and other variables that affect the timing of deliveries.

Learn more about ETA and other shipping terms.

FCL: Full container load

A full container load (FCL) is a type of payment option that can apply when shipping a lot of cargo at once.

FCL means that the shipper pays for a full truckload or container, no matter whether the truck is actually full.

You’ll get the whole truck to yourself.

This option is good for security compared to less-than-container-load (LCL) or less-than-truckload (LTL) because the FCL truck will stay closed until it reaches your destination only.

LCL: Less-than-container-load

Less-than-container-load (LCL) shipments refer to the event that a shipper’s cargo is loaded into a container or truck with other companies’ cargo, creating a mixed container.

This is usually a less expensive option than full container load (see FCL) shipping methods.

Check out our post on the cheapest way to ship large packages.

LTL: Less-than-truckload

Less-than-truckload (LTL) shipping is when one shipper’s cargo doesn’t fill an entire truck, and the truck is loaded with cargo from multiple shippers.

LTL is a specific term used in freight and small package deliveries, but it’s basically the same concept as less-than-container-load (LCL) shipping.

LTL is generally the less expensive option compared to full truckload (TL) shipping.

KPI: Key performance indicator

Key performance indicators (KPIs) are metrics used to track the performance of various business operations.

They’re usually calculated and monitored over time to track trends and fluctuations, allowing you to identify problems and areas of success.

Check out our post on the top supply chain KPIs to measure in 2023.

OS&D: Over, short & damaged

Over, short & damaged (OS&D) is an umbrella term used for shipments that arrive in imperfect condition — either damaged, short on quantity, or over quantity.

OS&D appears in aspects of the supply chain.

Many companies also use OS&D claims to let customers report problems with orders.

They might then focus on reverse logistics to pick the products back up.

TEU: Twenty-foot equivalent unit

Usually abbreviated as TEU, the twenty-foot equivalent unit is a unit of measurement mostly used in the ocean freight industry.

It’s based on the estimated 20-foot length of a standard shipping container.

So, you might read that a certain shipping vessel’s cargo capacity is measured in its maximum number of TEUs.

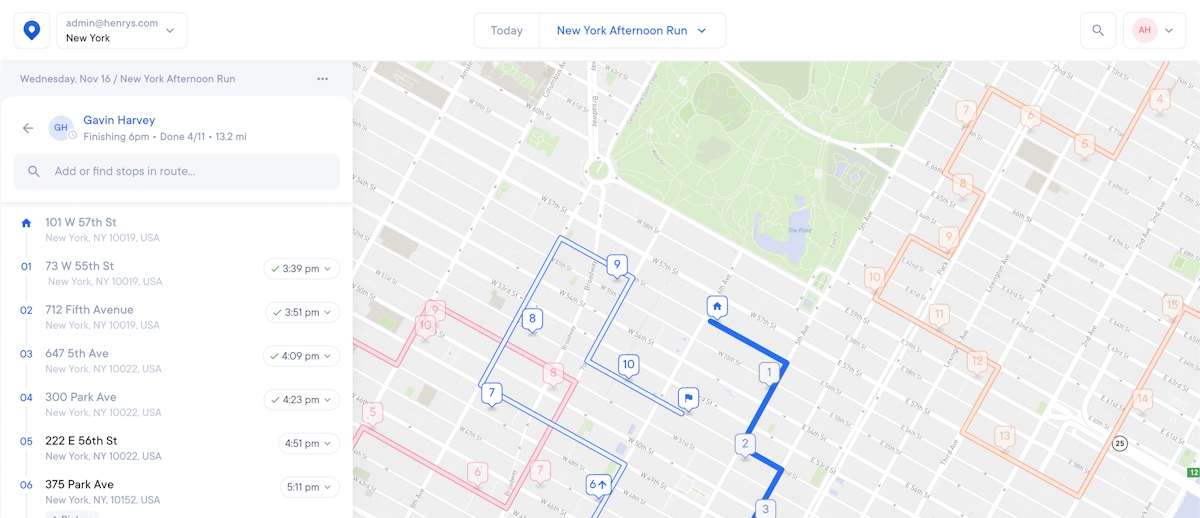

Shipping and delivering products yourself? Circuit for Teams simplifies the process

Learning all the important terms used in shipping and delivery can be challenging enough.

Save yourself some work by optimizing your delivery logistics with Circuit for Teams.

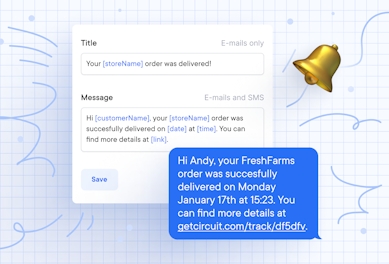

When your LTL customer is asking for an ETA on their huge PO, don’t sweat it. Circuit helps you send custom notifications automatically.

When you arrive JIT, you can easily collect POD with a digital signature or a photo.

Circuit has delivery analytics too, so you can track supply chain KPIs and keep your CRM filled with happy customers.