Manufacturing and Production Inventory: The Complete Guide

Learn all about managing manufacturing (production) inventory in this complete guide, including inventory types, challenges, and best practices.

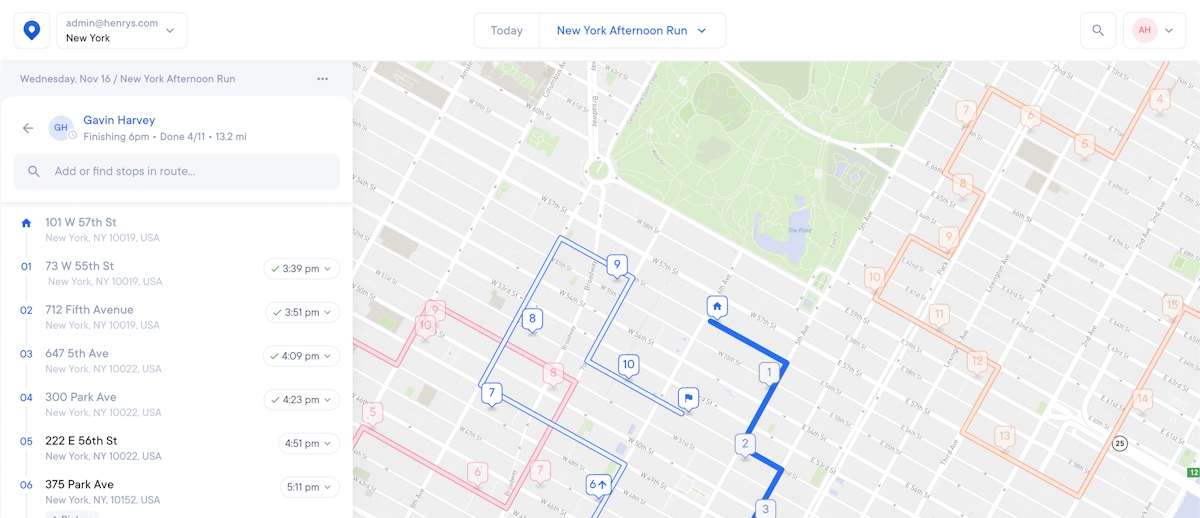

Have faster and smoother manufacturing inventory delivery with Circuit for Teams.

Managing your company's manufacturing and production inventory can boost customer satisfaction.

A strong grasp of inventory management can help you track stock levels and forecast demand. This will help you identify weak production areas and take steps to reduce your inventory costs.

This article will explain everything you need to know about manufacturing and production inventory. You can use this knowledge to optimize your company’s processes.

Key takeaways

- Managing manufacturing and production inventory improves customer satisfaction by guaranteeing products are available to meet customer demand.

- Effective inventory management optimizes production and resources by making sure the right amount of products are always in stock.

- Minimizing waste and holding costs can significantly improve your company's financial health by reducing costs and boosting efficiency.

- Manufacturing and production inventory best practices include using inventory control systems, creating lean manufacturing processes, and regularly reviewing inventory and reorder points.

What is manufacturing and production inventory?

Manufacturing and production inventory refers to a company’s stock of raw materials, components, work-in-process (WIP) inventory, and finished products. This inventory is the lifeline that keeps your production running.

Closely monitoring inventory levels, locations, and expiration dates can help you optimize your operations and increase purchase orders.

Manufacturing businesses have three types of inventory. Let’s explore each one and detail when and where they are used.

Raw materials inventory

A manufacturing company relies on raw materials inventory like a chef relies on fresh ingredients to cook a delicious meal.

Managing raw materials inventory includes tracking these materials’ quantity, quality, and availability. Effective management of raw materials is important for maintaining smooth production operations and making sure customer demands are met on time.

Work-in-process inventory

Work-in-process (WIP) inventory (not to be confused with “work-in-progress”) calculates the value of incomplete goods still in production.

Monitoring the production flow is the first task of managing WIP inventory effectively. This has many benefits, like reducing the lead time for manufacturing and improving productivity.

Finished goods inventory

Finished goods inventory includes the ready-to-sell products a company holds in stock. For example, think of a bakery that produces different types of bread. The finished goods inventory includes baked bread loaves that are ready to sell.

Maintaining finished goods inventory helps you fulfill customer orders quickly. This can also help you maximize sales opportunities since eCommerce distributors offering faster delivery service will likely encourage repeat orders and customer recommendations.

The importance of manufacturing and production inventory

Effective inventory management can help you prevent stockouts and excess inventory, so you can strike a balance between supply and demand. A healthy supply chain is one of the best ways to gain company success.

Here are some of the benefits a well-managed manufacturing and production inventory has to offer:

Optimizing production

Optimized production is one of the primary benefits of managing your manufacturing and production inventory. It leads to fewer delays and production bottlenecks, so you can fulfill customer orders in a timely manner.

Optimized production can help you swiftly produce more goods whenever you have more demand. This can boost your profits.

Meeting customer demand

We all like to believe we're one in a million, but the truth is that your customers might have other options that compete with your offerings.

Fail to fulfill your orders on time, and you might be kissing customers goodbye. Maintaining your company’s inventory levels can help you fulfill customer orders efficiently by preventing overstocking, shortages, stockouts, and delays.

Delivering orders on time is essential to customer satisfaction. Do this consistently, and your customers will likely make repeat purchases and recommend your brand to others.

Cutting costs

Reducing expenditures is a good way to increase your overall profits. Smooth manufacturing and production inventory processes offer many ways to cut costs, including:

- Preventing stockouts by estimating product demand

- Reducing lost sales by forecasting how many products you will need and making sure you have the right amount of inventory

- Minimizing waste and unnecessary expenses by streamlining production, optimizing order quantities, and making the best use of your storage space

- Reducing carrying costs of storage, insurance, and handling fees since you will only order the goods you need

Monitoring financial health

Good manufacturing inventory management can give you a clear picture of your company’s financial health. It involves tracking inventory items through every manufacturing stage: raw materials, work-in-process inventory, and finished goods.

Monitoring inventory turnover and carrying costs can help you check your operational process’s efficiency. And since proper inventory management can result in better cash flow and less excess inventory, it also helps you maintain a healthy balance between working capital and customer demand.

Challenges of manufacturing and production inventory

Managing your production processes and inventory levels has its benefits, but it also has some challenges. They can cause problems like stockouts, added costs, production delays, and ultimately, unhappy customers and reduced profit if left unaddressed.

Here are the main challenges of manufacturing and production inventory:

Forecasting demand and supply

This aspect of manufacturing and production inventory involves looking at past sales data, market trends, and customer habits to make sure you have enough inventory on hand to meet potential demand.

But customer demand and market conditions can change, and lead time can vary due to an unpredictable supply chain. These problems make it difficult to forecast demand.

This problem can cause an inventory imbalance, leading to either overstocking or stockouts.

Managing lead times and order cycles

Managing lead times and order cycles means optimizing the time between order placement and delivery. You must optimize production, coordinate with suppliers, and have good logistics workflows.

A manufacturing and production inventory imbalance can cause problems in managing lead times and order cycles. Longer production lead times might mean longer order completion times, leading to unhappy customers and lost sales.

Minimizing waste and inventory holding costs

An excess of unsold stock in your warehousing inventory is a burden on your balance sheet. Minimizing waste and inventory holding costs is important to reduce excess inventory levels.

Excess inventory ties up your capital in storage costs and leads to waste as inventory expires.

Unless you use automation (like a cloud-based inventory management system) to track manufacturing and production inventory and monitor stock remotely, knowing when you have an excess of unsold or dead stock can be difficult.

Manufacturing and production inventory best practices

Here are some key best practices for manufacturing and production inventory and the benefits of each:

Using inventory control systems

This gives users real-time visibility and control over inventory levels. Some examples of inventory control systems include:

- Radio Frequency Identification (RFID) technology for automatic inventory tracking and monitoring

- Barcode systems and SKUs for efficient product scanning and identification

- Inventory management software that centralizes inventory data and streamlines processes

- ABC analysis to categorize inventory based on value and prioritize management efforts

A good inventory control system might involve integrations of some or all of the above functionalities.

Implementing lean manufacturing processes

This means creating the most efficient production process possible to streamline or eliminate any aspects that don’t add value.

Let's review the lean manufacturing processes and how they can help your inventory management.

- Just-in-time (JIT) production: This reduces inventory levels by procuring materials and supplies you need to create or sell your products as you need them. Some real-world examples of JIT production include:

- Toyota’s assembly line: Toyota was among the first companies to use JIT production. They minimized their WIP inventory and storage costs and reduced excess inventory by ordering components from suppliers only as needed to fulfill orders.

- Fashion retailers: Companies like H&M use JIT production to keep up with fashion trends. They monitor customer demands and adjust their output accordingly, quickly introducing new styles and reducing unsold items.

- Continuous improvement (Kaizen): This process involves finding areas where you can improve processes, eliminate waste, and optimize efficiency by encouraging employees to contribute ideas to improve the company. You can use regular performance reviews and team brainstorming sessions to implement small-scale improvements to your processes.

- Value stream mapping: This refers to a visual aid that analyzes your supply chain to help you improve the flow of materials and activities that end in delivering a product. It can help you identify problems and things you can change to improve production.

- Standardized work: This includes establishing documented processes for completing tasks and classifying them as standards for workers to follow. This can help improve your company’s productivity, quality, and safety since giving employees clear guidelines improves consistency and output.

- 5S workplace organization: This improves workplace safety, productivity, and morale, promoting a culture of cleanliness and continuous improvement. It involves five key steps:

- Sort necessary items from unnecessary ones to keep only essential items in the work area, reducing distractions and improving productivity.

undefinedundefinedundefinedundefined - Kanban: This process involves using visual signs to control the flow of work or materials. An example would be using cards or boards in your factory to label inventory and show its location.

When employees know how much inventory is in your factory (and where it is), they can help reduce the risk of overproduction and maintain a smooth production flow.

Regularly reviewing inventory levels and reorder points

This involves monitoring and checking the quality of the inventory available to you. Completing a quality assessment can help you determine the right reorder point (what, when, and how much to reorder).

If you use inventory management software, you’ll also want to conduct regular physical inventory counts to make sure your records are correct. You can also help determine reorder points by analyzing past sales and demand data.

Improve your business with manufacturing and production inventory

Managing manufacturing and production inventory can improve your operations and bottom line. Tracking your raw materials, work-in-process inventory, and finished goods inventory using an inventory control system and lean manufacturing processes helps you keep an eye on the real value of your stock from start to finish.

Delivery is another important aspect of inventory and order management. After all, you’re still responsible for your inventory until it reaches its final destination.

You’ll need the most efficient delivery software to fully optimize your inventory management process. Try Circuit for Teams, and explore the best delivery optimization software on the market.